Client Context

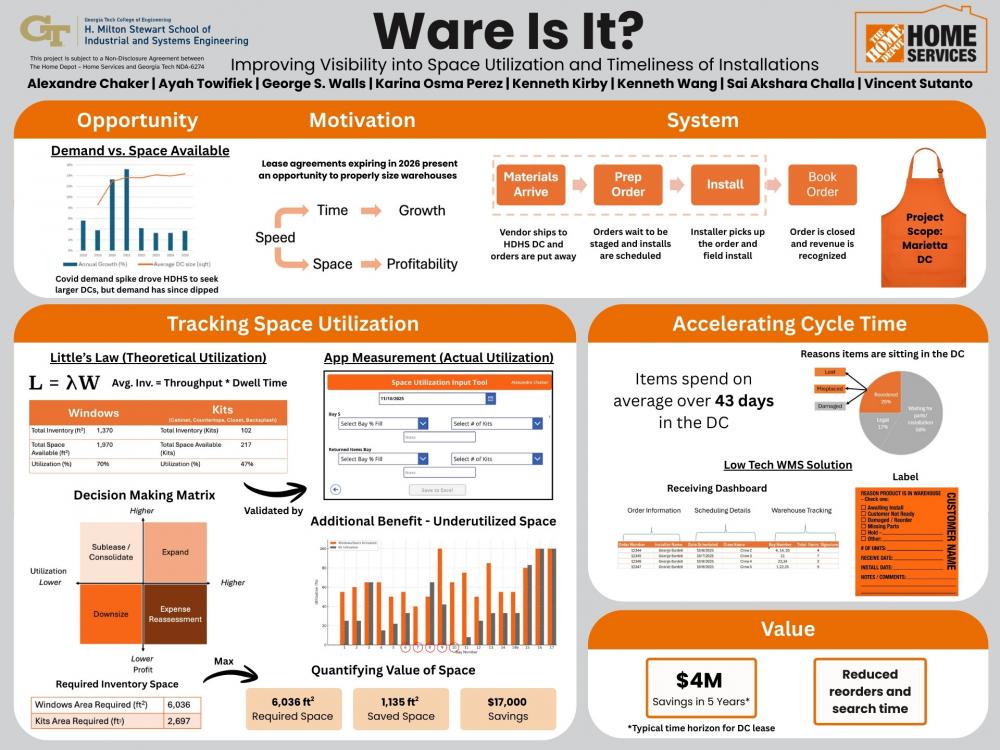

Home Depot Home Services (HDHS) oversees installations for products such as windows, kitchens, bathrooms, closets, and roofing. To support these services, HDHS operates a network of nationwide distribution centers (DCs) that receive materials from vendors, store them in bays, stage orders for installation, and release items to installers.

Our project focuses on the Marietta DC, where materials follow a defined workflow:

- Materials Arrive from vendors

- Prep Order – items are verified, stored, and staged

- Install – installers pick up staged items

- Book Order – revenue recognized

This system is central to HDHS performance because the DC acts as the transition point between material delivery and installation execution. DC processes directly affect speed, space usage, installation timeliness, and profitability.

Project Objective

Following the COVID-19 surge, HDHS expanded into larger warehouses. As demand has since stabilized, 2026 lease expirations present an opportunity to properly size DCs and reduce unnecessary space costs. At the Marietta site, items remain in the warehouse for an average of 43 days, causing congestion, lost or misplaced items, and delays for installers.

Our objectives were to:

- Provide visibility into actual space utilization

- Identify underutilized space

- Support right-sizing decisions such as downsizing, subleasing, or consolidation

- Accelerate installation cycle time

- Reduce lost, misplaced, and damaged materials

- Improve order visibility and communication between warehouse associates and installers

Addressing these objectives moves HDHS closer to goals of increased speed, growth, space efficiency, and profitability.

Design Strategy

1. Space Utilization Measurement

Methodology:

- Apply Little’s Law to calculate theoretical utilization for windows and kits

- Build a dynamic Excel calculator to compute required space

- Collect actual utilization through a Power Apps measurement tool connected to Excel

- Validate theoretical results against measured values

Validation:

Actual utilization closely matched theoretical estimates, confirming model accuracy.

2. Accelerating Cycle Time

Methodology:

- Identify controllable delays (lost, misplaced, damaged items)

- Introduce a Receiving Dashboard for visual job tracking

- Implement a standardized labeling system with bay locations and status indicators

- Apply principles of visual management, 5S, and standard work

These tools function as a low-tech WMS that standardizes tracking without requiring new software systems.

Deliverables

1. Space Utilization Visibility Tools

- Little’s Law Excel Calculator

- Space Utilization Tracking App (Power Apps + Excel)

- Decision-making matrix for warehouse decisions

- SOPs for both tools

How it helps:

Enables HDHS to understand current usage, validate capacity needs, and make informed lease decisions.

2. Installation Cycle Time Improvement Tools

- Receiving Dashboard (Excel)

- Standardized Labeling System

- SOPs for dashboard use and label population

How it helps:

Reduces search time, prevents misplaced items, increases order visibility, and improves installer readiness.

Value and Impact

Monetary Value

- 1,135 ft² of unused space identified at Marietta

- About $17,000 annual savings from right-sizing

- $4M potential savings over 5 years across the network

Operational Value

- Reduced search time

- Fewer reorders

- Faster installations

- Improved workflow reliability

Customer & Installer Impact

- Fewer delays

- More predictable scheduling

- Higher satisfaction and retention