Client Context

The Domestic Flight Kitchen (DFK) at Atlanta Hartsfield-Jackson airport plays a pivotal role in ensuring the timely and efficient preparation and catering of food and beverages to hundreds of flights daily. The DFK caters for an average of 350 flights daily. The demands of this high-flight volume necessitate a precise and well-coordinated operational process.

Delta currently uses an online web-based system called O2P (Open Operational Platform) that is managed by a third-party company. O2P determines the schedule and assignment of trucks, dictating departures times from the DFK, arrival times at the aircraft, and return times to the DFK. Within this system, a “trip” is defined as a driver’s journey from the DFK for delivery to aircraft and ends upon the driver’s return to the DFK. A driver can have up to three trips in one day and each trip can have up to three “deliveries”, meaning that there could be up to three aircraft they must attend to in a single trip. For each trip, trucks are loaded with an exact number of carts to cater to the one to three aircraft that the driver is assigned to, so once they are done with a trip, they must return to the DFK to start a new trip. The pairing of the flights for each trip depends on many factors, but the most important factors that O2P considers are the aircraft arrival time and type of aircraft. Trips take an average of two hours, and each aircraft takes a different time to cater.

Project Objective

The Domestic Flight Kitchen has been constantly facing challenges in managing overtime costs for the drivers during the truck delivery process.

Drivers are currently compensated at $18.20 per hour throughout their entire shift. Their overtime pay is 1.5x their hourly pay. The initial hourly wage, combined with the occurrence of overtime, adds to the overall labor costs of the DFK’s operations.

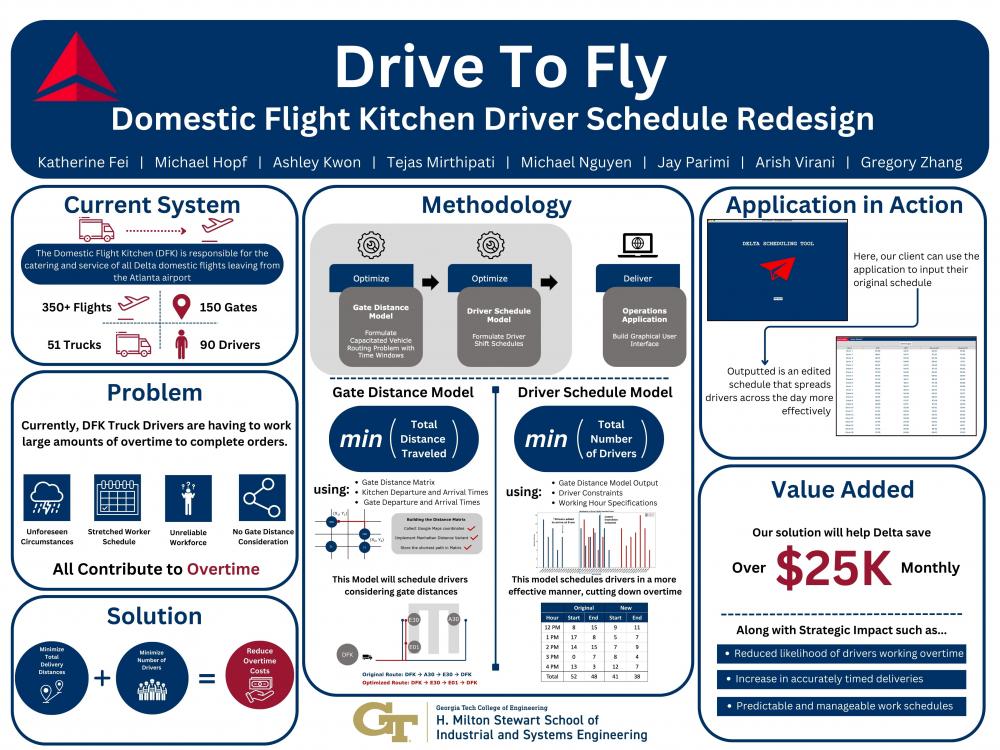

This project aims to reduce overtime by optimizing the truck delivery process in the Domestic Flight Kitchen. The key strategies include incorporating gate distances into trip planning to minimize total delivery distance and aligning driver shifts with flight volumes to strategically deploy the workforce, addressing stretched schedules and an unpredictable workforce. This holistic approach is expected to result in a substantial reduction in overtime costs for the DFK.

Design Strategy

The following strategic opportunities represent the team’s initiatives to enhance operational efficiency, reduce costs, and improve workforce utilization.

- Evaluate and Incorporate Gate Distances into Trip Planning:

The current O2P system overlooks the distances between each gate, leading to suboptimal trip planning. Integrating aircraft gate considerations into the existing O2P parameters offers a valuable opportunity to reduce overtime costs as it would minimize the total distance traveled during deliveries. This translates to shorter routes and reduces the time it takes for drivers to complete each trip. The resulting efficiency minimizes delays, guaranteeing that deliveries are completed within the planned time frame. By doing so, the team not only enhances overall logistics efficiency but also reduces the likelihood of drivers going into overtime.

- Realign Driver Shift Schedules to Prevent High Driver Shift Transition Time:

Aligning driver shifts with order volumes so that the DFK does not have shift changes shifts while demand is still present, ensures a strategically deployed workforce. This reduces disruptions during critical hours, enhancing the overall efficiency of the truck delivery process.

Deliverables

The final deliverable will be an operations application complete with a user-friendly graphical user interface. For the functionality of the model, two models are integrated in the backend. The Gate Distance model, a Capacitated Vehicle Routing Problem with Time Windows (CVRPTW), strategically minimizes travel distances between deliveries. The output of the gate distance model serves as an input for the second optimization model—the Driver Scheduling model. This model focuses on aligning driver shifts with flight volumes to minimize the number of drivers transitioning during the peak transitioning periods. The output of the driver scheduling model encompasses two distinct deliverables, integrated into the graphical user interface as part of the final operational solution. This strategic combination of models aims to provide a comprehensive and efficient approach to reduce overtime costs and improve overall logistics within the Domestic Flight Kitchen.

Value and Impact

By optimizing travel distances, the gate distance model ensures that drivers are scheduled to take the shortest possible route between deliveries. This approach will minimize the total distance traveled leading to shorter trip times. The resulting efficiency will lead to quicker and more accurate timed deliveries. As for the driver scheduling optimization model, this will address the problem of the stretched work schedule and unreliable workforce that the DFK is facing. By allowing the scheduling to take into consideration high flight volumes times and drivers’ schedules, the new model will eliminate shift changes during those times. This will lead to the reduced likelihood of drivers going into overtime as there will be allocated workers to take on these trips throughout a given day. This will also lead to the DFK having predictable and manageable work schedules as the workers are assigned to arrive at DFK throughout the day based on predetermined flight volumes and schedule.

For a sample medium flight volume day, the team has estimated approximately $18,775 dollars saved per month by the DFK.