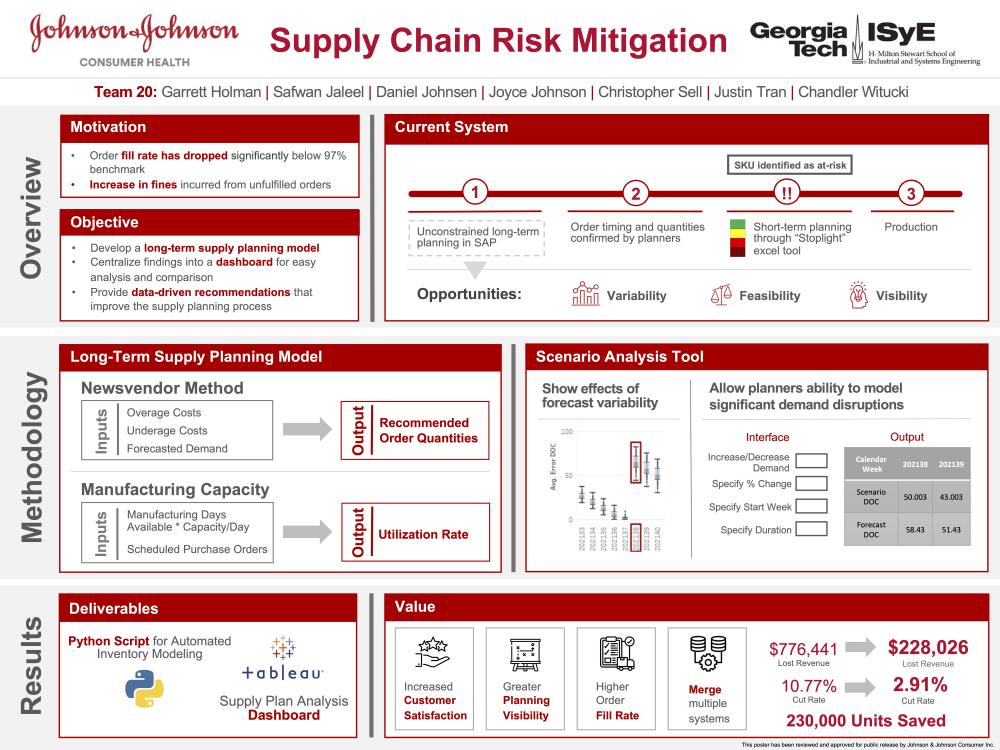

Client Context

Johnson & Johnson is an American multinational healthcare company that specializes in consumer packaged goods, medical devices, and pharmaceuticals. The Consumer Health division produces goods that touch over 1 billion lives each day, with the Inventory Management team responsible for generating and overseeing production plans related to these product lines. Our team worked specifically with supply planners for a manufacturing site under the North American Consumer Health division.

Project Objective

High demand volatility and disruptions related to COVID-19 have greatly impacted Johnson & Johnson’s ability to fill orders, reducing the order fill rate well below the 97% benchmark. The current environment has demonstrated a clear need for the planning process to account more robustly for variability and uncertainty. Our team saw an opportunity to support long-term order fill rate stability by providing a supply planning model and dashboard that include recommendations for an order plan, along with corresponding risk levels and costs.

Design Strategy

Our team began our work by devising recommended order quantities through the use of the newsvendor model over a fixed reorder time period. This was done to balance the risks of over and under-producing stock keeping units (SKUs) and adjust for historical demand forecast accuracy. The feasibility of this supply plan was then assessed through an analysis of manufacturing constraints, which takes into account order quantities of a particular SKU over the course of a month, and compares it to available production line capacity for the same time period.

We then began the development of a scenario planning tool to provide the planners with an analysis of our proposed supply plan in times of both expected and unexpected demand. To create a more informed view of supply outlook, we resampled historical demand forecast errors and fed them back into our tool to assess inventory position.

Deliverables

Our team had two primary deliverables. The first is a supply planning model. The model is a script written in Python that outputs raw data containing recommendations for a long-term supply plan and an analysis of that plan which accounts for potential demand forecast inaccuracies, manufacturing constraints, and demand disruptions.

The second deliverable is a front-facing Tableau Dashboard that helps supply planners visualize each of the outputs from our supply planning Python script. Users are able to filter the dashboard by each SKU. The dashboard enables the planners to visualize the effects of the changes made to the supply plan, evaluate any future risks they are taking on from their supply position for different SKUs, and smooth out long-term plans to ensure they provide feasible purchase order requests to their manufacturing sites.