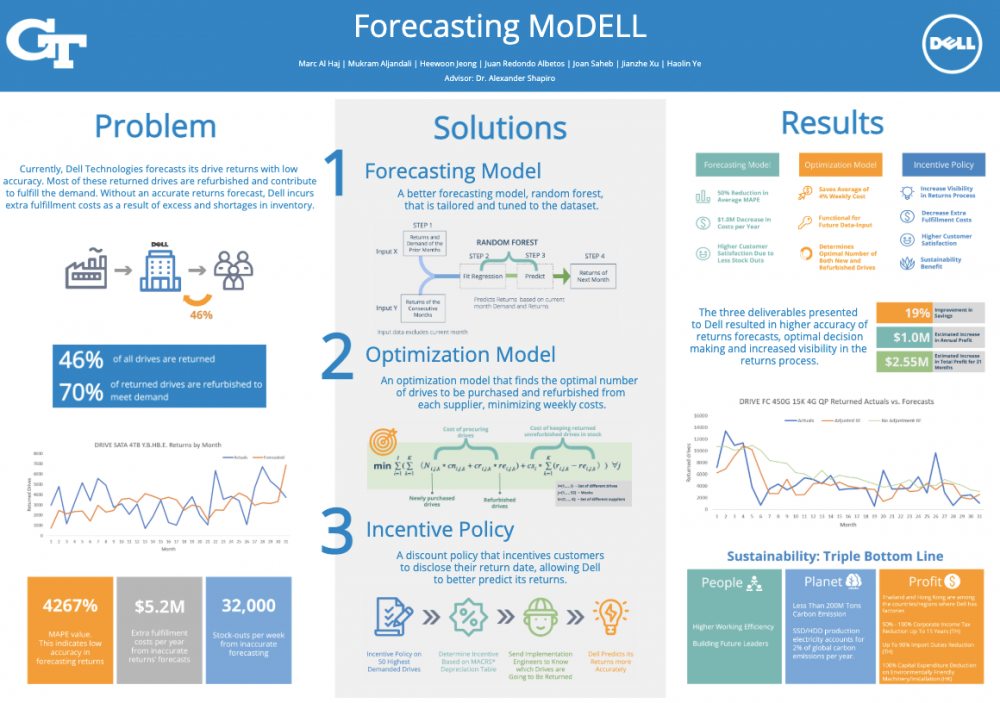

Client Context

Our client was Dell Technologies, the world’s 7th largest technology company. Through its main market, the infrastructure market, Dell sells servers, storage, and software to large enterprises. Our team worked specifically with the Supply Chain Data, Analytics, and Automation (DAA) team, which assists the planning organization in forecasting drives (SSD & HDD) from storage returns.

Project Objective

Although accurate forecasts of returns are critical, Dell currently has challenges when it comes to forecasting returns, averaging a MAPE value of 4267%, which has caused Dell to incur an extra ~$5.2 million in fulfillment costs every year and a high number of stock outs (~32k per week). Therefore, there is a clear opportunity to substantially decrease a significant part of those costs and reduce the impact that stock-outs have on Dell's customers and operations by better forecasting the number of drives returned to Dell. Thus, the objective of this project is to decrease extra fulfillment costs (both expediting and inventory) associated with the returns process in the following ways:

- Increase the accuracy of the returns forecast through a new forecasting model.

- Additionally, Determine the optimal quantities of purchasing and refurbishing drives that minimize the fulfillment costs while meeting forecasted demand through our optimization model.

- Potentially Increase visibility in the overall returns process through our recommended incentive policy.

Design Strategy

For our forecasting model, we first started by trying different models such as Auto-Arima and exponential smoothing. Then, we determined that Random Forest would be our model as it showed the best results among all models (by using MAPE as our metric of success). With the random forest model, we made modifications to make our model more reactive, and have it respond faster to sudden drops or rises in returns by:

- Scaling by the historical ratio of actuals/ forecasted

- Assigning scaling weights, with 50% of the weight being the All-month ratio, and 50% the last 2-month ratio

- Capping Ratios to a maximum of 4, and a minimum of 0.25

- Predicting based on data from the last 5-months only

Additionally, we created a model that optimizes the number of drives to be purchased and refurbished from each supplier each week based on multiple constraints including capacity constraints, supplier requirement constraints, and demand constraints from our client. This model is to minimize costs associated with fulfilling drives’ demands. We tested the model based on randomized but consistent data of multiple inputs that are necessary for our model. We then carried out a sensitivity analysis to test the effect of variability in our input to that in our output by generating 10 random forecasts of demand that follow the same distribution of the original forecasted demand and comparing the optimal value across these inputs. This resulted in an approximate 11% variability in the optimal value as a result of the variability in the forecasted demand, which we considered relatively low.

Although based on assumptions, the results of our third deliverable, the incentive policy, show that an implementation of the policy would be beneficial to Dell, with an expected Benefit to Cost ratio of about 2.5. Dell would further review the policy and see if there are opportunities to implement it.

Deliverables

Our team proposed a returns forecasting model with higher accuracy and additional recommendations that would help Dell decrease its fulfillment costs.

- Our proposed forecasting model is an original creation that uses demand and returns to make predictions. Moreover, our forecasting model smartly adjusts its monthly forecasts so that they become more reactive to trends and thus tailors its forecasts to returns.

- Our optimization model determines the optimal number of drives to purchase and to refurbish from each supplier, which would minimize the costs associated with fulfilling drives’ weekly demand. This operates within the constraints of capacity limits, supplier requirements, and client-specific policies.

- Finally, our last recommendation is an incentive policy that allows customers to get incentives if they notify Dell on when their drives will be returned, which would help Dell with its returns forecasting even further.