Client Context

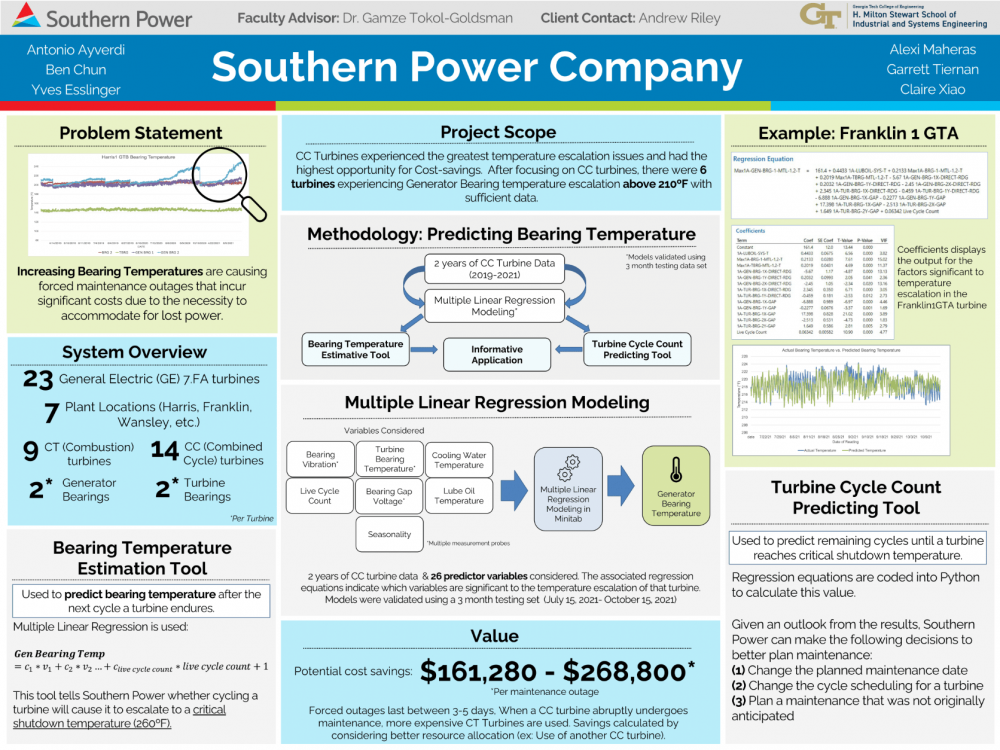

Southern Power Company (SPC), a subsidiary of Southern Company, is a leading U.S. wholesale energy provider meeting the electricity needs of municipalities, electric cooperatives, investor-owned utilities, and commercial and industrial customers. The company currently manages five natural gas turbine fleets in the southeast: Franklin, Harris, Wansley, Addison, and Rowan. SPC expressed concern that their turbines, specifically the combined cycle turbines (CC), experience increases in their bearing temperatures. Our project focuses on reducing the costs associated with bearing temperature escalation through better maintenance decisions.

Project Objective

Significant costs arise due to bearing temperature escalation. Once any of the bearings reach 265°F, the turbine must shut down to undergo maintenance to resolve the issue. High bearing temperatures shorten a turbine’s lifespan, increasing capital replacement spending. Additionally, while the turbine stays shut down, SPC must provide power from more costly sources to make up for the lost turbine, whether it be a more expensive turbine in their fleet or buying power from a third party. Without a full understanding of the causes of bearing temperature escalation, SPC experiences more frequent forced outages. With this, the team objective was to identify significant factors behind bearing temperature escalation. Additionally, the team aimed to provide estimates on how many times a turbine can be cycled (turned off and then back on again) before shutdown for use in maintenance and cycle planning.

Design Strategy

The team utilized Multiple Linear Regression (MLR) models though Minitab to predict bearing temperatures through identification of the significant factors behind these rising temperatures. After identification of live cycle count as a significant factor for all models, two of the MLR models and four Simple Linear Regression (SLR) models estimated the number of remaining cycles with a confidence range a turbine could endure before one of its bearings reached critical temperature. Finally, the team incorporated the capabilities of these regression models into a single informative application using a graphical user interface (GUI) in Python for SPC to easily access and utilize the bearing temperature estimative and remaining cycle prediction tools

Deliverables

1. Informative Application

The Informative Application harnesses the capabilities of the 6 regression equations and the tools previously mentioned by integrating them together into a user-friendly interface for SPC employees to 13 use. The graphical user interface (GUI) created through Python integrates the functionalities of both the Bearing Temperature Estimating tool as well as the Turbine Cycle predicting tool. The application homepage prompts users to choose one of the six turbines and then presents the associated screen that prompts the entry of the significant variables to the bearing temperature.

2. Bearing Temperature Estimation Tool

The inconsistent and sporadic behavior of bearing temperature poses a major challenge to SPC in predicting its short-term behavior. The bearing temperature estimative tool provides a remedy, giving SPC the ability to predict the bearing temperature of a turbine after enduring one additional cycle. This tool uses the regression equations output of each of the 6 MLR models.

3. Turbine Cycle Count Prediction Tool

The Turbine Cycle Count Prediction Tool uses the regression equations outputs from two of the MLR models and four single linear regression models to estimate the number of remaining cycles with a confidence range before the response variable bearing reaches critical shutdown temperature. SPC can use this tool to better plan maintenance in a variety of ways that prove cost effective.