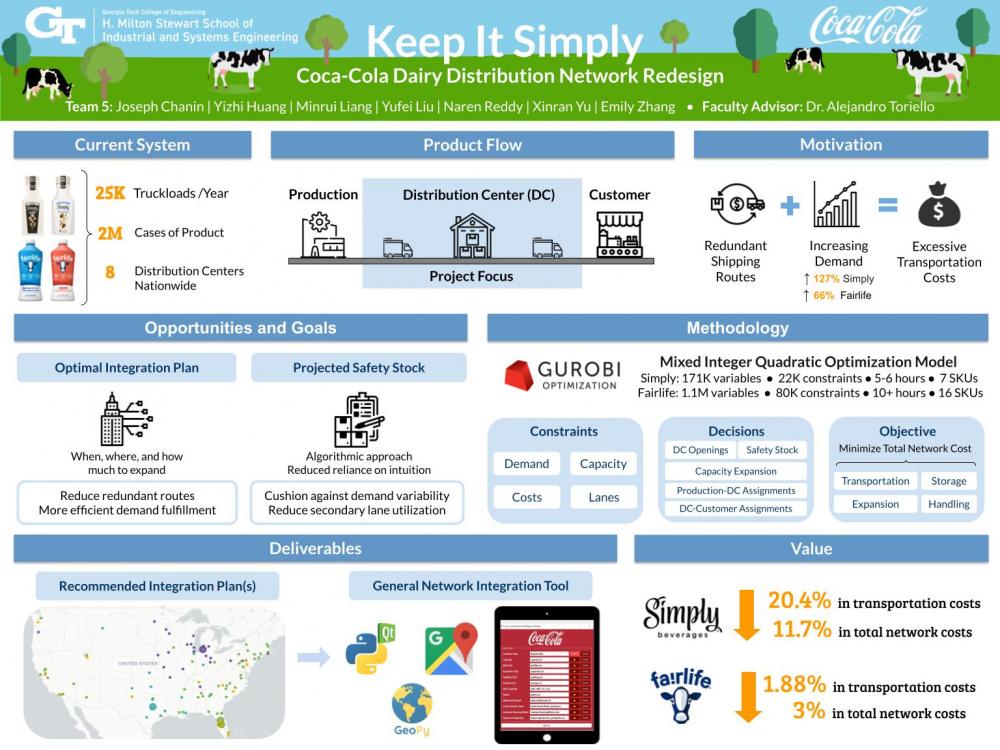

Client Context

The Coca-Cola Company is a beverage company based in Atlanta, GA with products sold in more than 200 countries and territories and several multimillion-dollar brands under its management. Two such brands are Fairlife, a brand of ultra-filtered milk acquired by Coca-Cola in January 2020, and Simply Beverages, which introduced Simply Oat & Almond (O&A) milks in April 2020. Around 480 truckloads of Simply O&A and Fairlife products are transported per week, together encompassing around 45,000 cases. For both brands, products are first produced in a production site, shipped to a distribution center (DC) for several days of holding time, and ultimately arrive at grocers’ DCs. The two legs of transportation account for the vast majority of the network cost.

Project Objective

Because Coca-Cola has not yet had the opportunity to completely integrate these brands into its chilled distribution network, it is concerned that the network will not be equipped to accommodate future growth in demand without incurring excessive transportation costs due to the sparsity of existing DCs. Because mileage directly influences transportation cost, and because existing DCs are not proximal to regions of growing demand, the network suffers from an inefficiency whereby the product often bypasses the final customer en route to its assigned DC. Moreover, the increasing demand for Simply O&A and Fairlife products further magnifies these inefficiencies. Currently, the Simply network consists of only three DCs in two states, while the Fairlife network consists of six DCs in five states to serve the nationwide demand. In order to accommodate this growth in demand, Coca-Cola seeks to integrate additional DCs across the United States into its chilled distribution network in an effort to reduce transportation costs, which is where we come in to help identify the most optimal expansion plans.

In addition, the customers are assigned to a primary DC and a secondary DC, where the secondary DC (usually farther away) will be used to fulfill customer’s demand in case primary DC runs out of stock. Thus, each DC must hold a designated amount of safety stock per month in order to protect against demand variability and to avoid the additional transportation costs associated with the utilization of secondary DCs. Currently, Coca-Cola relies on intuition to determine the safety stock level at each DC. We identified the opportunity to derive a standardized algorithm to help them calculate the optimal amount of safety stocks to hold for each product at each DC.

The project goal is to balance the two conflicting interests of reducing transportation costs and recommending safety stock levels that satisfy variability in demand in order to minimize total network cost for each of the two brands as well as any similar brands to be integrated into the Coca-Cola family in the future.

Design Strategy

In order to accomplish this goal, the project team constructed an mixed-integer quadratic program which is capable of recommending an optimal network integration plan based on Coca-Cola's monthly demand forecasts through 2023, suggesting capacity expansions at each DC to accommodate the greater flow of product, and systematically identifying the optimal amount of safety stock to hold at each DC to fulfill 98.5% of demand, a target specified by the client.

Note that the quadratic terms were introduced by including the calculation of safety stocks as a constraint in the model. Initially, the inclusion of the safety stock calculations introduced a non-convex constraint, which modern solvers are not good at handling. However, we were able to convert this to a solver-friendly convex constraint by squaring the binary term.

We validated our model results by confirming with the client contact that the breakdown of cost components and the opening decisions make inherent sense.

Deliverables

The team delivered detailed network design recommendations for both the Simply O&A and Fairlife brands. These include optimal production-to-DC and DC-to-customer assignments, DC opening timeline, capacity expansion levels, safety stock levels, and detailed cost breakdowns. The team also created a standardized tool, wrapped in a graphical user interface, that Coca-Cola can use to plan network integrations for any brand in the future. This tool can accommodate multiple use cases by offering three distinct options: safety stock calculations only, transportation routes optimization, and full-scale optimization with both safety stock and transportation considerations.