Client Context

Our team partnered with Novelis, an aluminum manufacturing company, to improve ingot availability in their Oswego, NY facility.

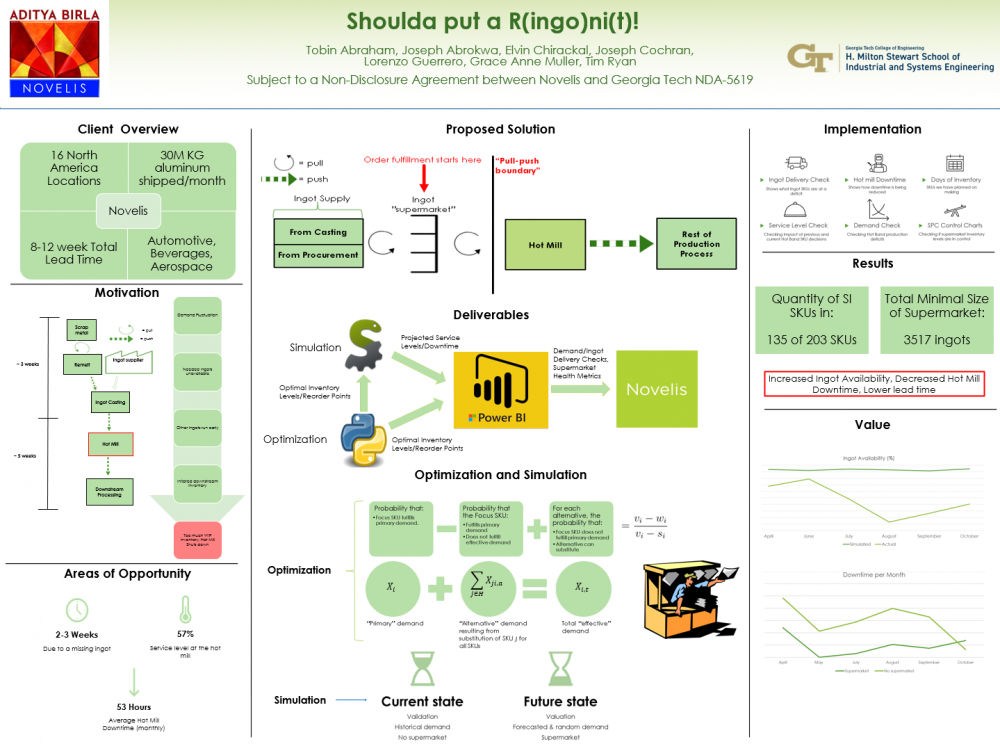

Most of Novelis' customers use a contract-based make-to-stock inventory system, meaning that the company is obligated to hold a certain quantity of finished goods in stock. For example, for a coil with a 10-week lead time, Novelis will produce enough coils to replace what the customer is planning to pull in 10 weeks. This requires them to build to their customers’ forecasts, but it also provides a buffer for the customer in case Novelis is unable to meet their production targets.

Novelis’ production process starts with the procurement of sheet ingots, which are large blocks of aluminum weighing 20,000-25,000 pounds each. These ingots can be purchased from an external vendor or produced internally by melting down scrap aluminum and casting it into a mold. The ingots are then run through a machine called the hot mill, turning it into a coil called a hot band. This hot band then goes through a series of different treatments depending on the product type before becoming a finished good. The entire lead time from procurement of an ingot to delivery of the final coil takes between 8 and 12 weeks.

Our project focuses on the hot mill, which is located at Novelis’ facility in Oswego NY. Currently, an MRP run in SAP is used to schedule hot mill usage to meet forecasted customer demand. There are far more finished goods SKUs than there are starting Ingot SKUs, as the overall process can transform a single type of ingot SKU into various finished good SKUs.

Project Objective

Novelis’ primary issue stems from ingot availability due to mismatches between on-hand inventory and actual demand. Each customer order begins when an aluminum sheet ingot is turned into a coil at a machine called the hot mill. Due to fluctuations in customer demand, there are often cases where the ingot Novelis planned to consume is no longer needed, and/or the ingot they need is not available. Since ingot procurement is a batch process, it is very difficult for Novelis to obtain specific ingots on short notice. As a result, the order is delayed while the correct ingot is procured, creating a backlog of late ingots and a poor service level at the hot mill. Furthermore, since the hot mill is the bottleneck of the system, Novelis is unwilling to shut it down, so when there no scheduled ingots available, they will process any ingots they have regardless of their scheduled due date. This processing of “unplanned” ingots results in increased inventory levels after the hot mill which clog the system by remaining in inventory indefinitely and can even cause the hot mill to become blocked, forcing a shutdown.

Design Strategy

Our solution was to create an ingot supermarket that will decouple the hot mill from the ingot procurement process. This ingot supermarket will maintain a stock of ingots in front of the hot mill that will increase ingot availability at the hot mill from approximately 70% to 90%. It will also shorten Novelis’ overall lead time by up to 40% by starting each order at the supermarket rather than the ingot procurement step. Finally, the supermarket will allow the hot mill to respond to changes in demand in real time and reduce downtime associated with poor ingot availability, driving cost savings.

Deliverables

To create this ingot supermarket, we created an optimization model in Python based on the classic newsvendor model. By calculating the costs of overstocking and understocking an ingot, we were able to determine the optimal reorder points for each sheet ingot SKU that would maximize overall ingot availability at the hot mill. We then used a simulation model (also in Python) to measure the impact of our supermarket on the performance of the hot mill. Finally, we built a PowerBI dashboard that displayed the results of both models, giving Novelis the information necessary to make procurement decisions moving forward.