Client Context

Smith+Nephew (S+N), a medical device and equipment manufacturer, has an orthopedic division with thousands of surgical products and tools, such as knee and hip replacements. This division is holding around $265 million in consignment inventory throughout the US. Currently, about 3/4 of this inventory is in hospitals while the remaining 1/4 is in storage warehouses called field locations. All products originate from one country warehouse in Memphis, Tennessee. In the system, units move from the country warehouse to field locations to hospitals to be used in surgeries, with short 1–2-day lead times. S+N owns the inventory until it is used in a surgery.

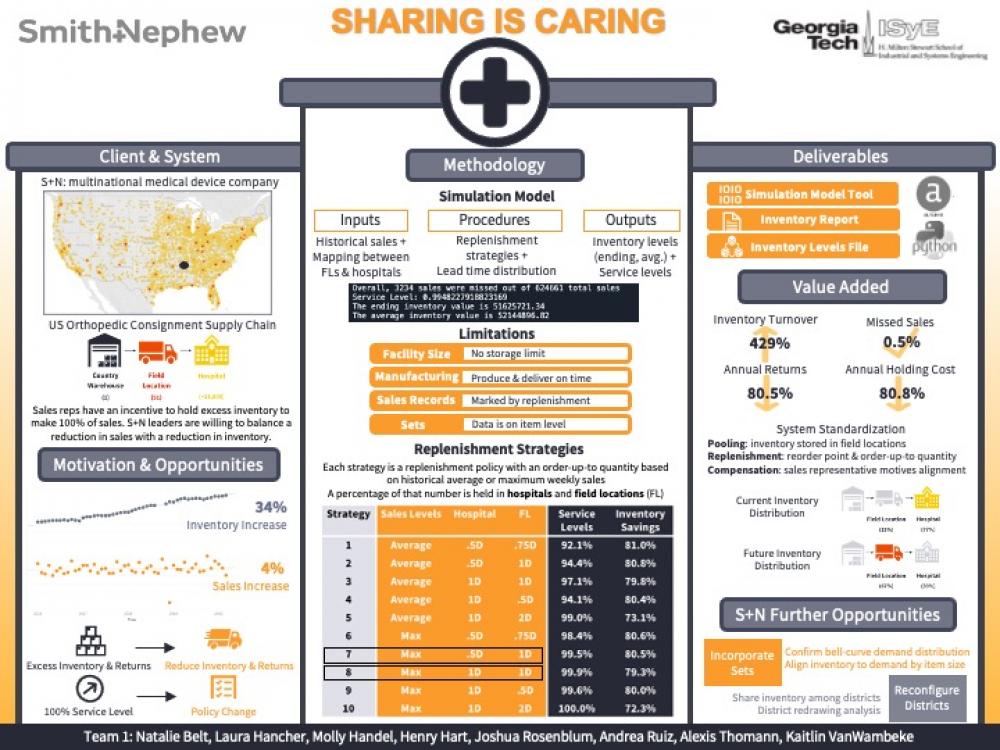

There are many different stakeholders in this system that have different motivations, but this project focuses on balancing the desire for near perfect service levels of sales representatives with the willingness of S+N leadership to slightly lower these service levels to reduce inventory costs.

Project Objective

Motivation:

Over the past 4 years S+N has seen a 34% increase in consignment inventory with only a 4% increase in sales. With this increasing inventory, the concerns for S+N are an increase in Excess and Obsolete (E&O) products, growth in holding costs, and low inventory turnover.

Opportunities:

The increase in inventory has also led to an excess in holding costs and returns that this project aims to reduce while limiting changes to S+N’s high service level.

A recommended policy change will prevent this problem from reoccurring in the future.

Design Strategy

The central part of this project is a simulation model that takes historical data and mappings between field locations and hospitals as inputs and applies a replenishment strategy similar to an (s,S) policy to output ending and average inventories as well as the service level for a time period.

The model works under unlimited facility size and manufacturing assumptions. There are also data limitations surrounding S+N's sales records and the availability of “set” (collection of different sizes of a specific piece of equipment) data.

There are 11 different possible strategies for S+N that we analyzed, but two were recommended to the client. The structure of these strategies is based on either the max weekly demand or average size of a sale and this value is set as D. As an example, strategy 1 uses the average demand and 50% of this value is held at hospitals and 75% is held at the corresponding field locations.

Deliverables

The simulation tool is a Python script imbedded in an Alteryx workflow that takes any S+N sales data and outputs the ideal inventory levels. This allows for changes to the inventory policy in the future because the client can rerun the script periodically with new data that might change the optimal inventory levels.

The report consists of the outputs from the simulation and analysis on the various strategies. This affords S+N the opportunity to determine which solution will be the most practical while satisfying their service level goals. It also consists of a long-term inventory return recommendation to prevent items from sitting in hospitals for their entire shelf life, and a sales compensation policy that will help align sales representatives’ motives with S+N leadership’s goals.

The CSV file includes the recommended strategy's inventory levels for each product in every hospital and field location. This gives S+N an opportunity to see where their inventory issues are since it can be compared to the current inventory holdings.