Client Context

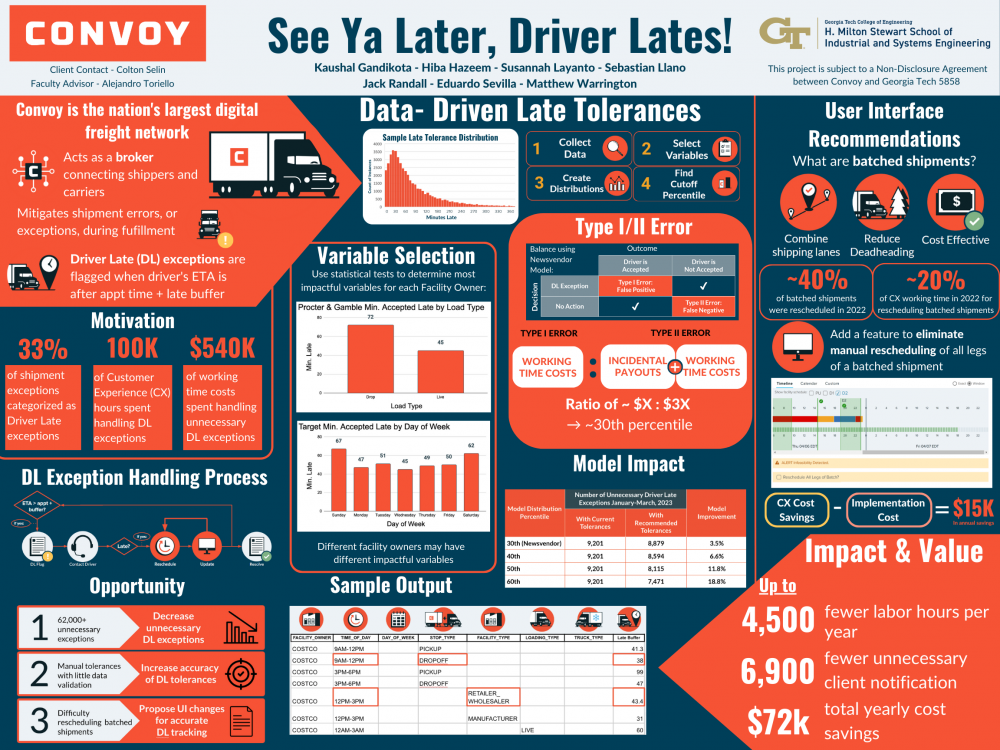

Convoy is the largest digital freight network in the nation, connecting shippers and carriers to create a more efficient and cost-effective freight network. Convoy acts as a third-party broker between shippers and carriers, and has a dedicated Customer Experience (CX) team responsible for ensuring customer satisfaction and reliability of service. During the fulfillment of an order, the most commonly occurring and most time consuming work item is a Driver Late exception-- an exception that occurs when a driver is projected to arrive late to an appointment. Around 45% of shipments with a Driver Late exception end up being accepted despite arriving late, meaning that many of these exceptions likely did not need to be triggered in the first place. This presents us with an opportunity to decrease the amount of time CX associates spend addressing these unnecessary exceptions.

Project Objective

Analyzing how Driver Late exceptions are triggered, we found that Convoy uses a model that includes a late buffer for each shipment, meaning that if a driver is projected to arrive at the facility within this late buffer, a Driver Late exception will not be triggered. These late buffers are currently set manually by account managers, with no analysis of historical data for how late facilities have accepted shipments in the past. To provide more accurate late buffers, we developed a model that analyzed historical shipment data to determine which shipment characteristics provide the most insight into how late a shipment can arrive yet still be accepted, as well as a data-driven number to use as a late buffer for these shipments.

Design Strategy

For each facility owner, we ran statistical tests to determine the two most impactful variables for how late a shipment could arrive yet still be accepted. Splitting up the data into smaller datasets for each combination of impactful variables, we then used the empirical distribution for mean accepted late arrival time to determine a more accurate late buffer. To pick a conservative distribution percentile to balance out any potential error in the model, we used a newsvendor model approach to determine a percentile that would balance the costs associated with false positives and false negatives in the model.

Deliverables

Additionally, through our analysis of Convoy's process for handling shipments, we noticed inefficiencies in how Convoy handles batched shipments, which are shipments with multiple legs that Convoy packages together to reduce a carrier's miles driven with an empty trailer. When a batched shipment needs to be rescheduled, a CX associate must navigate to multiple pages within Convoy's shipment management platform to manually reschedule each leg of the batch, rather than having a quick way to reschedule all legs of the batch at once. We provided a detailed analysis and proposal for including a button within the shipment management page to automatically reschedule all legs of a batched shipment, cutting down on time spent by CX associates and projecting to save Convoy $16,000 per year in labor costs.

Value and Impact

For both deliverables, we estimate total cost savings ranging from $25,000-$71,000 per year (accounting for implementation costs) and ~1,644 to 4,600 reduction in labor hours for Convoy CX associates. The variability of the valuations stems from the risk Convoy decides to take based on the tolerances from our model and the number of shipments they fulfill per year. Our recommendations also alleviate pain points for drivers, facilities, and shippers as they will reduce unnecessary client notifications and shipment reschedules, leading to higher satisfaction for all stakeholders involved.