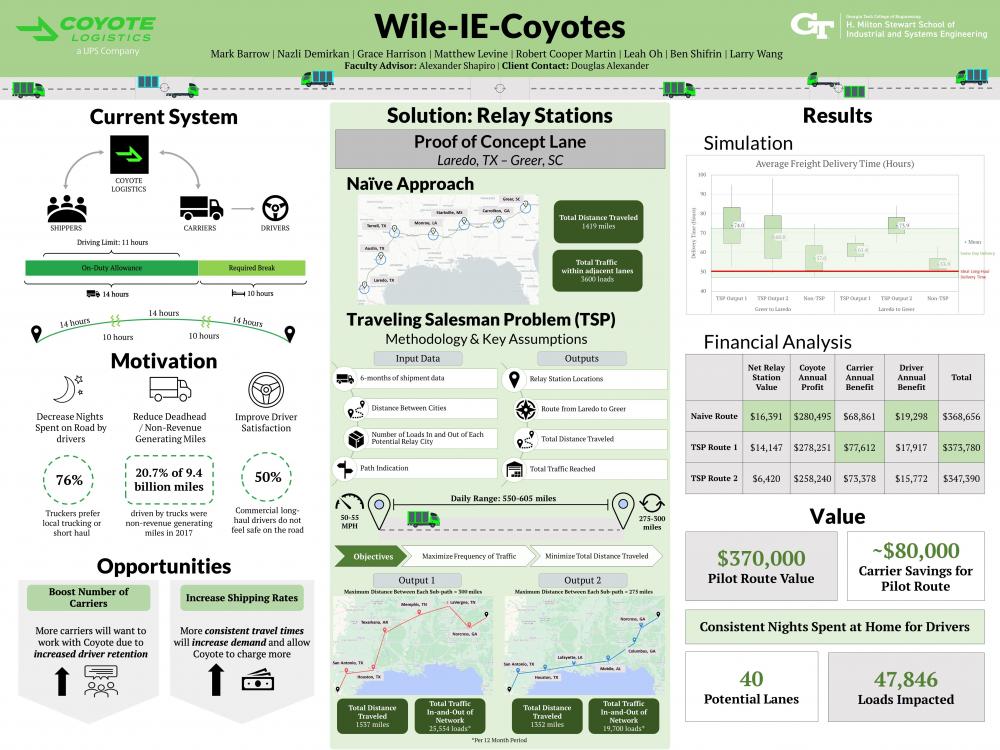

Client Context

Coyote Logistics is a third party logistics provider that combines a centralized marketplace with freight and supply chain solutions. Coyote has the third highest annual gross revenue in the field, working with around 70,000 network carriers and 14,000 shippers while coordinating about 10,000 loads of freight around the United States every day. Coyote became a UPS company in 2015, and prides itself on an innovative, start-up culture that can differentiate itself from its competition by implementing new ideas and therefore gaining more market share in the third party logistics industry.

The system the team is analyzing is the transportation of goods from one area to another through a trucking system. Coyote’s carriers transport these goods through two primary types of truck loads: full truck loads (FTL), in which a truck is filled to maximum capacity with a good, and less than truck loads (LTL), in which a truck is not filled to maximum capacity.

Project Objective

Carriers are currently struggling greatly with driver retention. As a whole, the trucking industry saw its annual driver turnover rate reach 89% for large for-hire truckload carriers in 2018, a massive amount of turnover for any industry.

Coyote has attributed much of this turnover rate to driver dissatisfaction. Long-haul truckers spend anywhere from seven to twelve days away from home at a time, leading to negative impacts on mental and physical health, in turn leading to quitting their work prematurely. Since the minimum estimated cost of having to hire a new truck driver was $3654.72 in 2018 ($4310.60 in 2022, adjusted for inflation), keeping consistent drivers could save Coyote’s carriers hundreds of thousands of dollars annually. By ensuring that their carriers’ drivers are satisfied, Coyote’s likelihood of being hired as a broker by more carriers has the potential to increase dramatically; therefore, Coyote’s primary concern is decreasing turnover rates by increasing driver satisfaction, which can be achieved by lowering the number of nights drivers spend on the road and away from home.

Another problem that carriers are facing is deadhead miles, miles driven by a truck driver without a load of freight attached to their truck. This not only costs truck drivers money, as they don’t earn wages while they aren’t transporting goods, but carriers as well. 20.7% of 9.4 billions miles driven by trucks were non-revenue generating miles in 2017, a massive number considering how detrimental deadhead miles can be to drivers and carriers.

Design Strategy

Through research done by the client, it was determined that implementing a system of relay stations across Coyote’s network of shipping lanes could greatly increase driver satisfaction. Relay stations are generally a large guarded parking lot that drivers use to perform the “drop-and-hook process”, in which one truck driver will unhook the trailer from their truck and then hook a new trailer up to drive back the way they came. A different driver will then hook the original trailer to their truck, and continue towards its final destination, either completing the shipment or stopping at another relay station to perform drop-and-hook again.

Deliverables

To create a recommendation for relay station locations, the team used historical data from Coyote’s six months of shipments from March 7, 2022 until September 7, 2022. The six months of historic shipping data was used to determine an initial area for examination due to the large scale of Coyote’s operations in the United States. Delivering a recommendation for locations throughout their entire network would have been impossible; therefore, the team sought to provide these locations along a single Coyote lane as a proof of concept, allowing Coyote to test the results on a small scale before expanding the system nationwide.

It became apparent to the team during initial research that there were many factors that affected time on the road for truck drivers that could not be extracted from the data: high traffic volume, poor weather conditions, and trucker’s preference in route navigation are among the most unpredictable. Furthermore, the route’s status as a proof of concept required it to be useful towards Coyote’s future expansion plans. Therefore, the team decided it would be in Coyote’s best interest to provide them with multiple routes that the company can examine using factors that the team wasn’t given access to, as well as factors that may simply not have presented themselves yet for the future of the relay station system.

As one of the options presented to the client, the team decided to create a route using only Coyote’s most simple constraints; this became known as the “naive route,” referring to the naivety of the assumption that no optimization past the initial constraints was required that led to its creation. Since the majority of Coyote lanes are located north of Texas, a more northern route should also theoretically be more beneficial for future expansion of the system. Using these constraints the team created a route stretching between Greer and Laredo containing relay stations in urban areas, per Coyote’s request, in order to ensure that there is a large enough population that there will be enough drivers to staff these routes.

To ensure that the relay stations chosen have high potential to accommodate other routes in the future as well, the team used a Traveling Salesman Problem (TSP) approach to evaluate the route between Greer and Laredo. The objective is to select a set of relay station cities with high frequency of loads in and out, while minimizing the total distance traveled between Greer and Laredo.

It is important to not increase the delivery time to deliver from Laredo, TX to Greer, SC or Greer, SC to Laredo, TX when choosing the cities with high potential. According to the client’s data, the average distance traveled between Laredo and Greer by a driver was 1302 miles. Considering Key Assumption 1, it can be assumed that a shipment traveling on this route would usually take 3 days. If the relay station network's total distance traveled results in the shipment taking longer than 3 days the shipper would experience a delay.

The objective of the model uses a weighted sum method by assigning weights in terms of importance on the two sub-objectives: (1) maximize the total sum of the number of routes the relay network accommodates within the six-months data and (2) minimize the total distance traveled between Laredo and Greer.

The team’s second deliverable was a financial analysis in Excel that will allow Coyote to input costs per mile, hiring cost, cost per relay station, number of relay stations and drivers, number of shipments, driver retention rate, annual deadhead, profit margins, and revenue split, to estimate the monetary value of each route to Coyote, the carriers, and the drivers. Coyote will be able to use this document to analyze the relay stations’ costs, benefits and to decide their break-even point.

Value and Impact

Coyote finds value in this project in two key areas: increasing the number of carriers that work with Coyote and by increasing Coyote’s profit margins through higher shipping rates. The team used the financial analysis to determine that the value of the pilot route to Coyote and its carriers is over $340,000 regardless of which route they choose. Furthermore, this will present Coyote with the future opportunity to expand this system to 40 other potential lanes that have similar characteristics in size and delivery levels. Moreover, this specific pilot lane has an estimated cost savings of around $70,000, in driver retention and decreased deadhead miles, for the carriers that Coyote works with.

Therefore, the team is confident that it is in Coyote’s best interest to examine the created route recommendations, determine which one best fits their needs, and implement it as a pilot route. Coyote will have to keep in mind certain risks such as pushback from carriers and shippers, loading and unloading times at relay stations, coordination between truckers, and more random factors such as traffic and potential weather delays. Regardless of which route is chosen, all have potential to give drivers the opportunity to spend less nights on the road and significantly reduce deadhead miles.