Client Context

Delta Air Lines is one of the largest airlines in the United States, with a revenue of $54.7 Billion in 2023. Delta has several hubs in the United States – the largest of which is Atlanta. Atlanta is also home to Delta TechOps, which is the airlines’ primary maintenance location. Delta’s main storage facility in Atlanta is comprised of two locations: Delta TechOps Base and Pelican Warehouse. Pelican Warehouse is responsible for processing all used or returned parts that arrive in Atlanta by truck, which is roughly 2,500 individual parts per day. Due to space constraints at Base, these parts are processed in Pelican and stored at either Pelican or Base. Pelican normally stores large, heavy, non-dangerous items. However, there are many other types of material (snacks, Wi-Fi kits, small airplane parts) also stored on their shelves. The rest of the items are sent to Base.

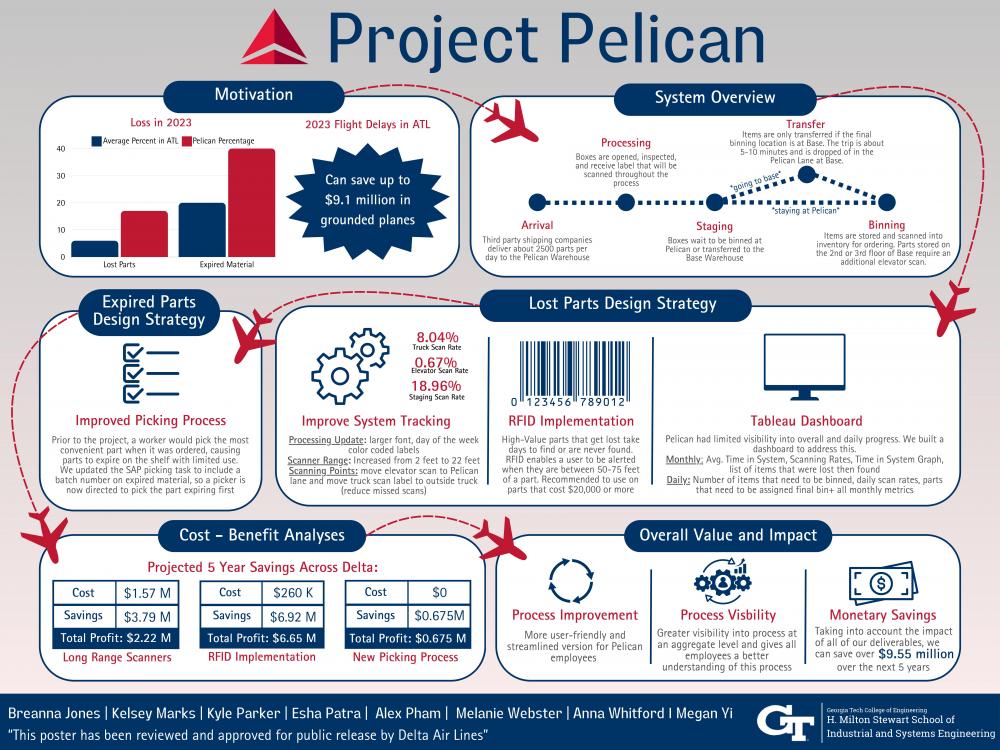

Project Objective

Delta’s priority for Pelican Warehouse is getting parts where they need to go quickly and accurately. However, shortcomings of the scanning process and item tracking impede their success – parts go missing daily and take hours/days to be found or are never found and must be repurchased. This is not sustainable: Pelican loses millions of dollars' worth of parts throughout the year and pressure is put on the workers to stop their assigned tasks to search for parts, slowing the overall process. Next, part of Pelican’s inventory can expire (this can include items such as metal, rubber, and food) when stored on the shelf for too long. Any reduction in unused material scrapped due to expiration date will save Delta money. Our team’s objective is to reduce the number of lost parts, decrease the number of items expiring on shelves, and provide improved visualization for part tracking.

Design Strategy

We took a human-centered approach combined with gaining a deep understanding of Delta’s systems and the Pelican Warehouse’s processes to best provide multiple smaller but more feasibly implementable solutions. From numerous discussions with our clients and surveying employees, we developed a design that improved the quality of life for employees and the ease of their jobs, to improve overall system performance. Throughout learning Delta’s processes, we worked closely with our client for approval and ran test implementations to validate our approach.

Deliverables

To address the issues regarding lost parts, we delivered five different solutions. After speaking to management and employees, we discovered that boxes could have multiple barcodes, which is confusing to workers when they scan these barcodes into their system. We recommended color coded stickers for each day of the week. These colors help distinguish between relevant barcodes and find items when misplaced. For example, if a lost part was processed on Monday, the workers know they are looking for a box with Monday’s color sticker. We also suggested they increase the font size on the labels. So far, color-coded stickers have been implemented.

To address the scanning issue, we delivered a cost benefit analysis to Delta leadership on improving the scanning range from two to twenty-two feet. This would allow forklift drivers to remain on their forklift when they need to transfer parts between stages – cutting down on time and missed scans. We also recommended new scanning locations because some of the current scanning locations were redundant and inconvenient. We chose locations that provide the same data but are easier for workers to scan. This will reduce the number of skipped scans and create a more accurate tracking system.

Additionally, we provided a cost-benefit analysis for RFID tracking on parts valued at over $25,000. RFID makes it significantly easier to locate items – meaning this solution would decrease the time spent searching for lost parts and reduce the amount of money spent repurchasing these parts.

Lastly, to reduce the number of lost parts we designed a Tableau dashboard to help workers visualize their system on an aggregate level. This dashboard shows key metrics (time in system, scan completion, etc.) at a daily and monthly level and splits these metrics into items stored at Pelican and Base. This helps workers identify bottlenecks and keep track of items that are more likely to get lost.

For the second part of our design strategy, there was one deliverable. We added an addition to their current pick tasks. If a pick order contains an item that has an expiration date, that item will have a batch number assigned to the task. This batch number will require workers to pick the item that will expire the soonest. This will reduce the amount of material that expires on the shelves. Currently, there is a pilot test of a small batch of expired material at Pelican. It will be implemented across the whole warehouse inventory in the next few months.

Value and Impact

The overall impact of our project can be split into three sections – process improvement, process visibility, and monetary savings. The changes to the scanning and picking processes improve the overall system operation, making it more user-friendly and streamlined. The dashboard gives employees more visibility into their system and allows all employees to pull aggregated data. The implementation of SLED-based rules is expected to streamline warehouse operations by ensuring timely usage of inventory to minimize the risk of part expiration. With the implementation of long-range scanners and RFID and the reduction in scrapped/unused material due to expiration, Delta’s Pelican Warehouse system can save up to $11.5 million in the next five years.