Client Context

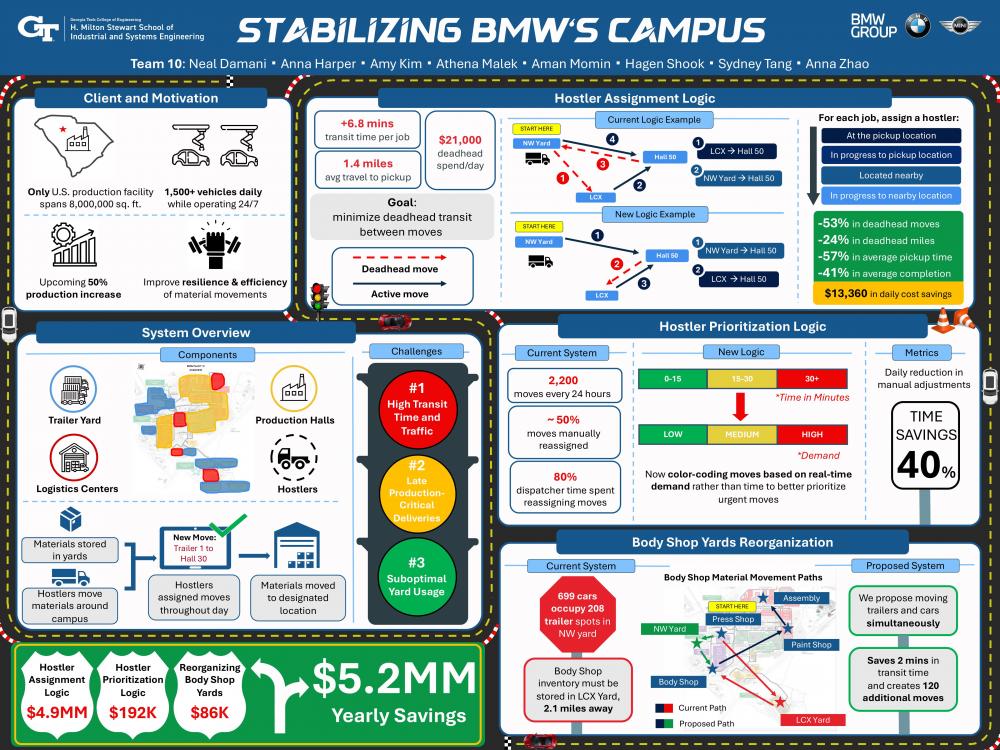

Our client, BMW, is a large German luxury automotive company. In 2024, BMW sold 2.5 million passenger vehicles worldwide, of which 450k were produced at their only U.S.-based production facility, in Spartanburg, South Carolina. Our goal is to improve the resilience and efficiency of material movements within the facility in preparation for a planned 50% production increase.

Project Objective

We identified three target areas to improve in the material movement process: high transit time and traffic, late production-critical deliveries, and suboptimal yard usage.

The root cause identified for deliverable one is deadhead moves—non-material movements—which significantly increase a job’s total transit time and campus traffic congestion. BMW currently spends $21K per day on these moves, and they account for 27% of all daily miles driven. We are reducing deadheads by improving BMW’s move assignment logic, saving costs on driver movements and fuel usage along the way.

Our second deliverable targets late production-critical deliveries by redesigning the dispatcher screen’s color-coding logic. On a dispatcher’s screen, move requests are color-coded red, yellow, or green based only on their time spent in queue. The colors help dispatchers prioritize moves but do not account for production urgency, leading to an increase in urgent moves and close calls with production shutdowns. When needed, dispatchers manually reorder these moves, accounting for 80% of their work time. Our new logic adjusts the visualization screen to color pending moves by demand instead of time in queue.

Finally, the yard used to store Body Shop inventory is located 2.1 miles away from the Body Shop; however, there is another yard—the NW yard—only 0.5 miles away. Currently, finished car inventory is occupying 2/3 of the NW yar space. Utilizing this space properly is important because 29% to 95% of all moves going to the Body Shop take over 30 minutes. Every move routed from the farther yard adds two minutes in transit time, accounting for about 120 moves lost per day. We target this problem by running a cost-and-feasibility analysis on relocating these trailers and finished cars to better-located yards.

Design Strategy

The new logic for our first deliverable creates a more dynamic, proximity-based system by reducing queue size and redrawing boundaries of nearby buildings. It first searches for the earliest available hostler at a pickup location, then checks for the earliest hostler en route to the pickup location. It then searches for the earliest available hostler in the nearby area before searching for the earliest hostler en route to the nearby area. If 14 minutes pass and no hostlers fall within the parameters to pick up that move, the search is expanded to the rest of campus. This simulation takes in system parameters including hostler fleet size, queue size, neighborhood groupings, deadhead distances, and moves to be assigned. To replicate BMW’s assignment system, we programmed the script to import moves from a 24-hour period of move data. Initial testing was based on the current fleet size of 36 with the new logic, neighborhood groupings, and queue size. Based on the deadhead distance and overall time reductions, we lowered the number of hostlers until we reached a balance between metric improvement, traffic congestion, and cost savings from the reduction in fleet size. The system with 33 hostlers, queue size of one, and neighborhoods based on distance yielded the best results. To test the resilience of the proposed system, we increased the number of moves by 50% to simulate BMW’s production increase.

For deliverable two, we developed a Python simulation to compare the shutdown risk of the current and proposed material request systems. The simulation runs two replications. The first models the current system, where moves enter and exit the queue using a first-in, first-out (FIFO) method. The other situation models the proposed system, which mimics system-dispatcher interaction where jobs with higher demand are moved to front of the queue. Both situations iterate every 15 simulated minutes, using consumption rate and current inventory levels to look an hour ahead into the queue and prioritizing moves to reduce shutdown risk. To validate our model against variability, we conducted a paired-sample t-test on time in each zone. Our findings show that the change in time in all zones is statistically significant in both the current and increased production results.

For our third and final deliverable, we conducted a cost and feasibility analysis of three potential options for moving finished cars: car carriers, moving cars as trailers are requested, and simultaneously switching the cars and trailers. The simultaneous switch option offers the simplest logistical implementation and lowest cost, making it our recommended approach. Additionally, with the production increase, the internal resources necessary for this option will be readily available.

Deliverables

Our first deliverable consists of an implementation guide containing an explanation of the proposed logic, system simulation results, and financial quantification with plans to go live in the BMW system on May 5th. Our Python logic simulation results in reduced deadhead moves, miles, transit times, and hostler count. This logic reduces current material transit time by 41% and will decrease average transit time by 31% after the 50% production increase.

Our second deliverable is an implementation guide showing proof of concept for our proposed change in logic, which has been furthered to IT for implementation discussions. The new colors will help prioritize moves based on production urgency, helping mitigate shutdowns even with increased volume. This updated system decreases time spent on manual adjustments by 40%.

Lastly, we provided BMW with a cost analysis and implementation guide for our recommended option of simultaneously moving the cars and trailers. This change will save two minutes per body shop move, creating availability for an additional 120 moves per day. BMW’s senior leadership team is currently discussing a timeline for implementing this solution.

Value and Impact

With deliverable one’s reduction in deadhead miles, truck driver fleet size, and both direct and indirect operational efficiencies, it contributes to $13.3K of daily cost savings—approximately $4.9 million annually. The second deliverable results in yearly cost reductions of $192K from dispatcher time savings. Finally, the yard reorganization results in daily savings of $236 in fuel alone. Across these three deliverables, the savings total $5.2 million annually. Beyond financial gain, our solutions ensure that BMW is prepared for its 50% production volume increase and that the Spartanburg, SC campus remains resilient.