Client Context

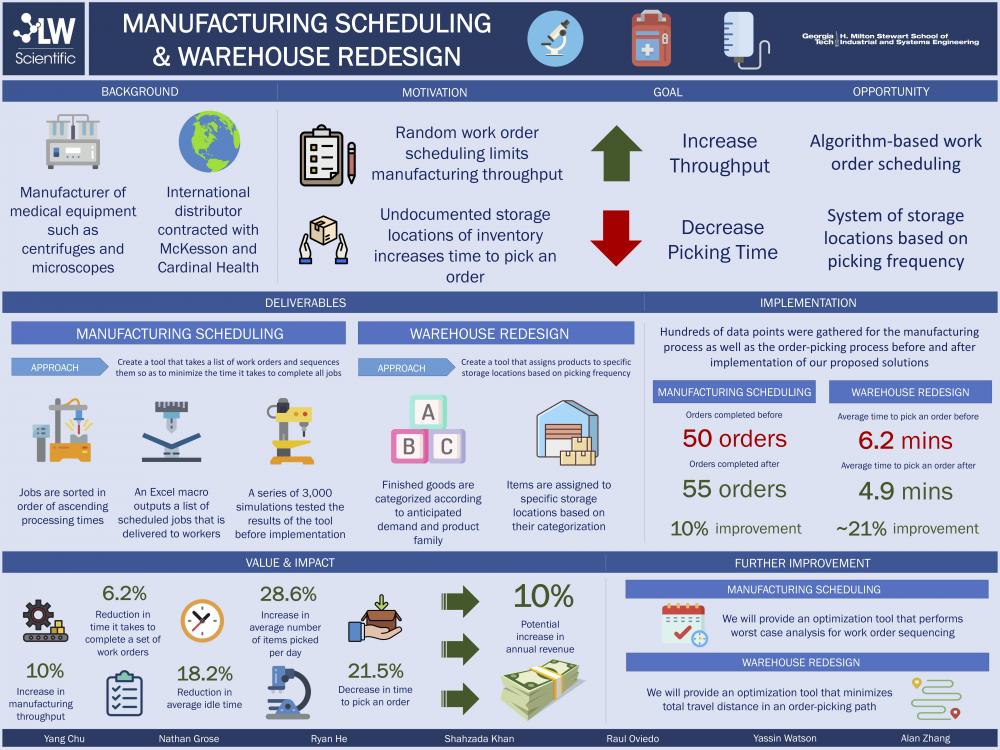

LW Scientific (LWS), headquartered in Lawrenceville, Georgia, is a manufacturer and international distributor of medical products including microscopes, centrifuges, etc to companies such as McKesson and Cardinal Health. Most of LWS's product line is currently outsourced from suppliers in China. But to reduce variability in lead times and costs associated with tariffs, LWS wants to relocate its manufacturing and warehousing operations from China to the US.

LWS’s in-house manufacturing process consists of a production line (shop floor) and an assembly station. The production line has three separate machines which include a laser cutter, a press brake, and a pem inserter. Work orders are scheduled by the production manager based on the demand of products in past sales orders. Additionally, inventory in the warehousing area of the Lawrenceville facility consists of finished goods manufactured on-site and finished goods outsourced from other manufacturers.

Project Objective

LWS is looking for opportunities to increase revenue by increasing capacity. Over the past year, they had around $500,000 in unfulfilled orders due to capacity constraints of their Lawrenceville facility. These capacity constraints made it infeasible to fulfill the volume of demand in a timely manner. We identified opportunities in the manufacturing and warehousing processes to be able to cover that unmet demand, and we worked with the client to identify the goal of increasing manufacturing throughput by 10% in addition to decreasing the average time to pick an order by 10%.

To address the volume of demand, the scheduling of work orders in the manufacturing department was analyzed. We identified that random work order scheduling led to throughput limitations, so the opportunity was presented to deliver an algorithm-based tool which reduces the time it takes to complete a list of work orders by resequencing the order of jobs.

To address the timeliness of order fulfillment, the warehouse layout was redesigned. We observed that employees faced difficulty locating items in the warehouse. This presented the opportunity to create a system of identifying storage locations and deliver a tool to assign inventory items to specific locations based on their anticipated demand.

Both subprojects worked towards increasing product throughput through the facility in order to fulfill previously unmet demand and, thus, increase overall revenue.

Design Strategy

For the manufacturing scheduling subproject, we created a tool that utilizes Johnson's Algorithm in order to optimally sequence work orders in the manufacturing line. Since some assumptions in Johnson's Algorithm differed from those of our client's system, we needed to take additional steps to prepare for cases when certain conditions are violated. In order to account for those situations, we built a mixed integer linear programming model using Google's open source library, Google OR tools. In addition, in order to account for variability in the machine processing time, we built a robust optimization model to analyze the performance of mixed integer linear programming and Johnson's Algorithm in worst case scenarios.

For the warehouse redesign subproject, the design strategy included addressing the layout of goods within the warehouse and also the picking path used by an order-picker to retrieve items for an order. To address the layout of goods, an ABC Model Storage System was created from an ABC analysis, in which products were categorized based on their picking frequency and assigned to specific locations. To address the picking path, the Capacitated Vehicle Routing Problem was applied to the order picking system in order to create a tool that outputs the optimal picking path given a specific picking order.

Deliverables

For the manufacturing scheduling subproject, we delivered a macro that outputs the optimal sequence based on application of Johnson's Algorithm. We also created a Google OR-Tools Python package that outputs sequence (with minimized completion time for an entire list of work orders) of work orders on each individual machine in the manufacturing line. Lastly, we provided a robust optimization tool as a python package that will output the optimal sequence of work orders in best case and worst case scenarios.

For the warehouse redesign subproject, an ABC tool was developed to assist the client in assigning SKUs to rack locations in the warehouse based on their picking frequency, given a product line and its corresponding historical sales data. We also delivered a picking path tool that outputs the optimal picking path given a specific picking order.