Client Context

Coca Cola Bottling Company United (CCBCU) is the 3rd largest bottler for Coca Cola, with $2.9B in annual sales. For this project, the team worked with the South Metro sales center, the largest in the East Region, processing over 35 million cases of product annually. At a high level, product is created at a production center, sent to be stored in a sales center such as South Metro, and eventually picked for customer orders. Once each order is assembled on a pallet, drivers deliver orders to the customer site. If a case of product is damaged either in transit or at the customer site, it is returned to the sales center, where unsalvageable product is recycled and salvageable product is repackaged into new cases to be resold.

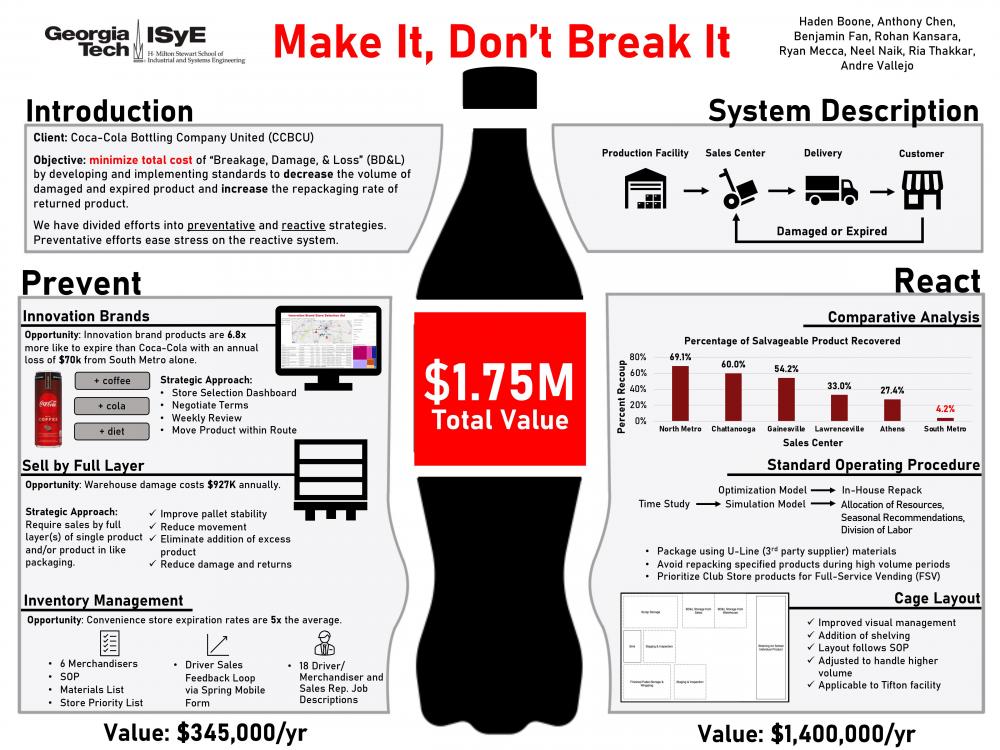

Project Objective

Leadership identified the cost of broken, damaged, and lost BD&L) product, which consists of damaged and expired product, to be a substantial area of opportunity at South Metro due to a high volume of returned product of which only a small portion is successfully recouped. In fact, South Metro’s recoup rate of salvageable product is 4.2% compared to a company-wide average of more than 45%. To reduce the occurrence of BD&L as well as increase the recoup of product after it is damaged, the team identified three primary opportunities. The first of these was a high rate of expiration of innovation brand products (i.e. new flavors or package sizes introduced to the market) in stores. The second was a high rate of expiration of product at drug and convenience stores due to a lack of proper organization in store backrooms. The third and largest opportunity is the low rate of repack at South Metro, which stems from an unorganized repack area at the warehouse as well as understaffing. Addressing the high rates of expiration mentioned in the first two opportunities can prevent BD&L in the first place, and designing a solution for the third opportunity can vastly increase the amount of product that is successfully reintroduced into the broader system that together can have a substantial impact on the client’s bottom line.

Design Strategy

The team divided into two work streams: one focused on prevention of breakage and expiration, and the other focused on recouping the cost of returned product. From the proactive side, the team visited multiple client sites to identify opportunities in the system, where they discovered the high expiration rates of innovation brand product, and disorganization in convenience store back rooms. The team conducted many client interviews to determine the most implementable and cost-effective strategies to mitigate these two issues. On the reactive side, the team conducted a time-motion study on the repack process at a comparable sales center with a significantly higher repack rate of 60%. The data from this study was used to create an optimization model for determining the optimal location of repack, as well as a simulation model depicting the repack process in order to test the throughput of our newly designed repack system at South Metro.

Deliverables

The team had three primary deliverables. The first was a strategy to mitigate expiration of innovation brands, including an interactive dashboard that suggests specific stores to roll out new products to. The second was a strategy for inventory management, in which it was suggested that temporary employees be hired as "floating merchandisers" to travel to customers with high expiration rates due to disorganization and set up FIFO inventory policy. The third was a new repack standard operating procedure, including suggestions to use easier and cheaper materials for repack, implement a new repack area layout with visual management systems, and hire additional employees for two shifts to best handle the throughput of returned product.