Client Context

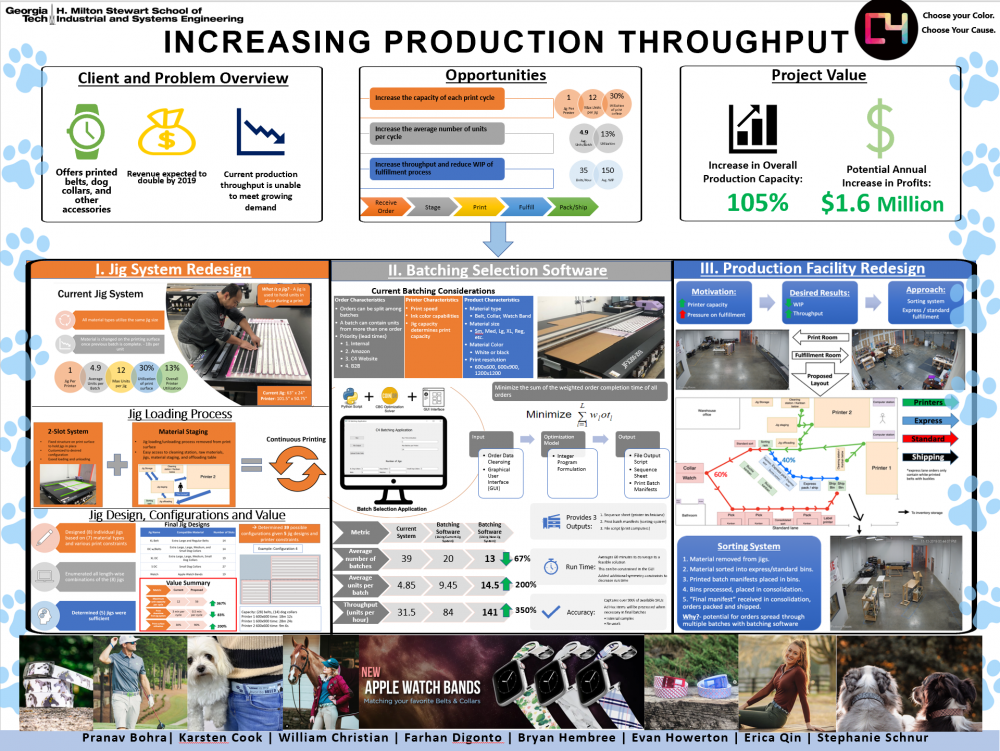

The team partnered with C4 Belts (C4), a brand of Niche Digital Brands (NDB), a portfolio company of digital brands that targets pet and animal lovers with niche products. C4 Belts offers buyers personalized, colorful, and eco-friendly belts, apparel, equestrian accessories, and dog collars. Founded in 2011, C4 Belts currently employs about 20 people. As the company is still investing to keep up with the growing demand for its products, most of the financials are in the red. Over the past two years, C4 has recorded a 12% decrease in gross profit margin due to COGS and growing expenses (77% and 58% increase over the past 5 months, respectively) as they are expanding production to meet demand. The company is on target to double its sales from 1.2 million to 2.4 million in 2019 and is projecting more than twenty million in sales in the next five years. As a result, the company moved to a larger facility in Norcross to expand their operations in July of this year. The team is primarily working with David Lefkovits, the Chairman and Owner, Michelle Der, the CEO, Johnny Trotter, the CFO, Frank Fernandez, the COO, and Dany Fernandez, the Warehouse Manager.

The current product offerings can be divided into two main categories, Custom Printed Products and Repackaged Products. The current product portfolio of C4 Belts is listed below: Custom Printed Products, Repackaged Products, White base belts (regular and XL), Solid colored belts, Black base belts (regular and XL), Skinny belts, Dog collars (small, medium, large, XL), Buckles, Watch bands (one size, white base only), Socks and other accessories (e.g. hats, keychains, posters). The orders are received from various sales channels and then routed to the production floor. C4’s sales channels include Amazon, Web (Shopify), and B2B/Wholesale. B2C orders are direct to customer and have a lead time of four days. B2B orders are typically more flexible and have a lead time of seven days and are not prioritized as highly as the B2C orders (Amazon and Web). B2B orders are larger in size and are typically produced over a period of a few days. Once the orders are received by the production team, the units are printed in batches by sales channel and order. Once units are printed, they are transferred to the fulfillment process. The fulfillment process includes assembly (matching the printed belts with the proper buckle, or riveting the dog collars), picking (sorting each unit into its proper order), packing, and shipping. Once the order is packed, a shipping label is pasted on the container and the order is ready to be shipped. The repackaged products follow a similar flow, bypassing the print process and move straight from order routing to assembly

Project Objective

C4 Belts is a brand of Niche Digital Brands (NDB) located in Norcross, Georgia. C4 Belts prints patterns on plastic belts with color inks according to the specification received from customers. With upcoming demand growth, it was necessary for the company to re-evaluate its current printing production and order fulfillment processes, as the current system is underutilized and operates with several inefficiencies. The printing process was identified as the bottleneck in the production process. Therefore, to increase the total production throughput, the project focuses on increasing the printers’ capacity and utilization. The team observed that approximately 70% of the available printing surface is unutilized. The first aspect of the project was to take advantage of this available print surface by designing a new structure for units to be printed on the printers’ surfaces that holds multiple jigs of different sizes. Each new jig was designed to maximize the capacity of each print cycle while considering the necessary constraints of the current print process. Additionally, the team redesigned the system by which units are loaded and unloaded from the print surface to allow the printers to run continuously while the next batch is prepared, and the previous batch is unloaded. In order to effectively use the new jig system, the team created an optimization model that determines the most efficient batching sequence for that particular day’s orders. The model takes several variables into consideration including order priority, material type, and print resolution. Currently, print jobs are batched based on sales channel (B2B/Wholesale, Amazon, and web orders) and are grouped by material type by a printer technician before the production shift starts during the “preflight” or staging step. According to time study data, the utilization of the printers is approximately 13% with a combined hourly throughput of approximately 35 units. The proposed model automates the preflight process, decreases the number of print cycles that are necessary to meet current demand (by increasing the average batch size), and increases the utilization of both printers in the system. The optimization model will work in tandem with the new jig design allowing for an increase in total capacity and utilization of C4’s print process. Because the above-mentioned solutions achieve a higher throughput for the print process, the downstream fulfillment process could potentially become the new bottleneck in the system. The batch selection tool adds a layer of complexity for the order sorting process as there are currently no unique identifiers for each unit as it flows through the system, apart from a physical packing list which travels with each order throughout the process. To mitigate this, the team developed and implemented a new warehouse layout and sorting system. By implementing the solutions above, C4 is able to increase their print capacity and increase overall production throughput. With this increase, the team expects C4 to meet its growing customer demand.

Design Strategy

The objective of the project is to increase the throughput of the production system. The team identified three key strategies to accomplish this goal. As the bottleneck of the production system is the printing process, the first two deliverables increase the efficiency of the printing process by increasing the print surface utilization, simultaneously printing and preparing batches for printing, and optimizing the batches, while the third deliverable relates to order fulfillment, to account for the downstream effects of the changes to the print process. Before developing the deliverables, the team spent extensive time in the system evaluating the current system processes by doing time studies, conducting interviews with employees, and observing processes. Additionally, the team consulted with outside vendors and manufacturers to confirm the feasibility of certain design strategies. On the back end, we ran simulations using 15 days worth of historical data to simulate results of the software.

Deliverables

Jig System Redesign - redesigned physical jigs and created jig configurations to use as input data into our model. Modified physical loading process and created slot system on surface of printer to increase surface utilization and allow for increased capacity.

Batching Selection Software - coded optimization model in python that takes in sales data and minimizes the weighted completion time of orders and creates a series of outputs to guide printer technicians through production process.

Production Facility Redesign - redesigned physical layout and sorting process to accommodate increased capacity and throughput of printing production.