Client Context

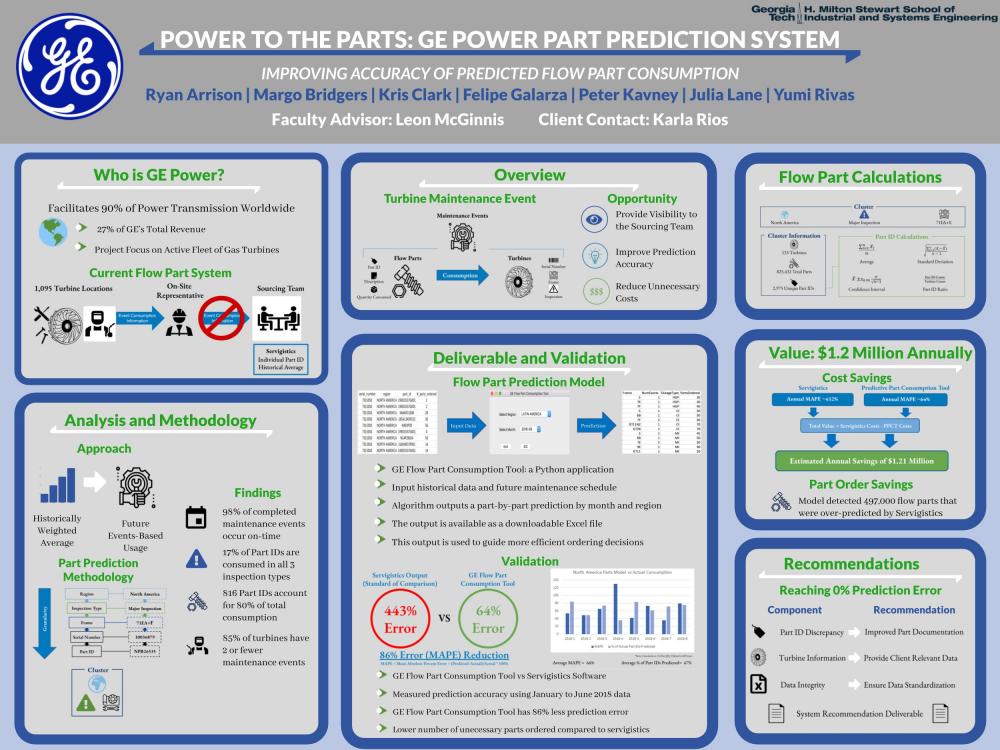

General Electric (GE) is a global digital industrial company that offers products and services in a wide range of industries. The division of GE that this project focuses on is GE Power. GE Power specializes in power generation technology, power grids, and energy management software. This project focuses on GE Power’s fleet of gas turbines.

A Gas turbine is the engine at the heart of a power plant that produces electrical current. Due to extreme temperatures and moving parts, a turbine must undergo various maintenance events over the course of its 30-year lifetime to keep the machine running at peak performance. These maintenance events occur every few years. When this happens, the machine is shutdown and inspected to see which components need to be worked on or replaced.

The team focused on the smaller parts of the turbine that would potentially be replaced. These smaller parts are known as flow parts specifically. This is the term used by GE to describe small, consumable, wear-and-tear parts on the turbines such as seals, gaskets, nuts, and bolts.

These are consumed by the turbine for each maintenance event. These flow parts are requested by a GE power maintenance personnel after they conduct a scheduled maintenance inspection. Based on the condition of the turbine, flow parts are requested to service the upcoming maintenance.

GE has a team called the Sourcing Team that’s functionality is to determine the consumption of flow parts for a given turbine. Due to the high volume of maintenance requests, the sourcing team makes predictions using a software called servigistics. Servigistics makes predictions on a part-id specific level using historically weighted averages of the parts that were consumed for a given turbine. Since flow part consumption is dictated by discrete consumption events, there is an opportunity to incorporate all event information that the Sourcing Team, the team we’ve been working with, currently doesn’t utilize.

Project Objective

There is an opportunity to improve the current process used to predict flow part consumption by utilizing information about turbine maintenance events. This led us to more accurately predicting the consumption of flow parts. This was done by providing the sourcing team with visibility to the events in which the parts were consumed. This means that we incorporated information about the inspection type, region, and turbine frame, that GE was not utilizing. This will allow the sourcing team to have an accurate number of flow parts on hand when needed, which in turn will reduce unnecessary costs associated with the ordering of flow parts.

Design Strategy

Our approach for developing our methodology was first taking into account what information influenced flow part consumption. The first analysis looked at the scheduling of the maintenance requests. Our findings told us that we can make the assumption that when a maintenance is to occur, it happens at the time the GE sets. Our findings also showed that the type of inspection of the maintenance influences part consumption.

Based off of this information about their current system, the best approach for our project was transitioning from servergistics methodology of predicting based on the historically weighted averages of each part ID to predicting using a maintenance event based approach. This means instead of just looking at how many parts were ordered, we are looking to what factors played into those parts being ordered.

We tested and validated this methodology by comparing part consumptions between historically weighted averages with part consumptions that had taken inspection type region, and turbine frame into account.

Deliverables

Predictive Part Consumption Tool (PPCT): Predicts flow part consumption by month and by region. The PPCT provides the Sourcing Team better visibility to future maintenance inspections and the predicted parts associated with those events.

Recommendations document: Will outlines recommendations for GE Power to better the data collection and documentation processes, so that prediction accuracy can further improve.