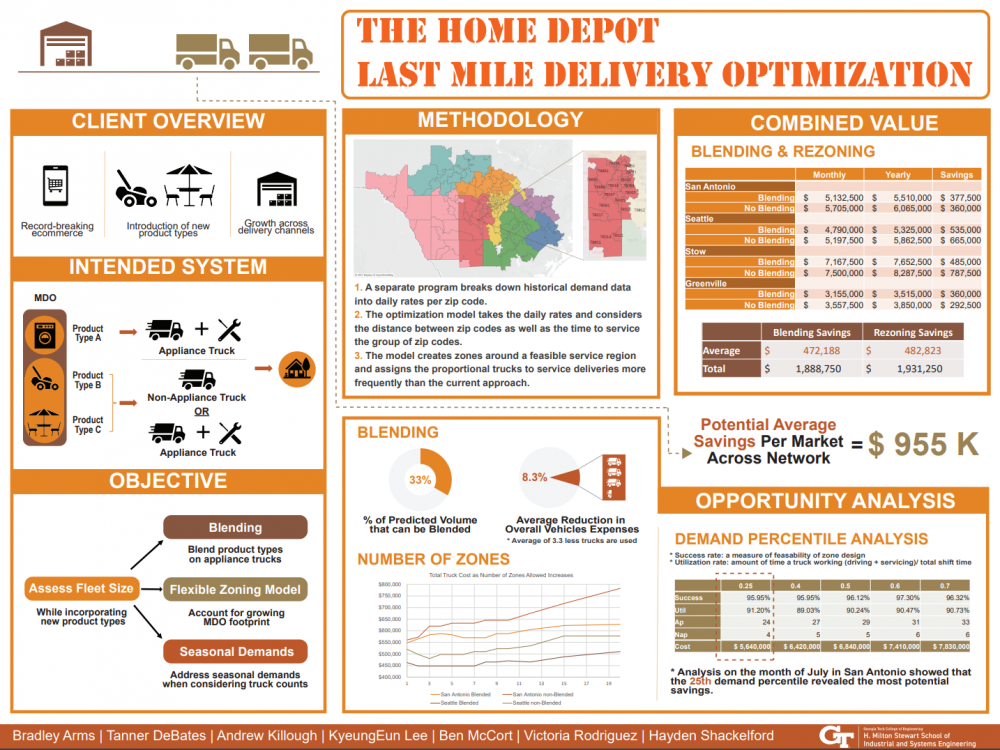

Client Context

The Home Depot is the world’s largest home improvement retailer with over 2,300 retail stores across North America. According to The Home Depot’s 2020 Investor’s Report, commerce from digital platforms experienced an 86 percent growth compared to previous year’s revenue. The data analytics department recognizes the opportunity to redesign their delivery network to accommodate for this growth and further support expected consumer demand. The goal of this project is to create a quick and repeatable tool to determine a zoning process to be utilized by The Home Depot’s cross dock facilities, which they refer to as Market Delivery Operations (MDOs). MDOs use the concept of delivery zones to service customers. The current market regions are generally composed of multiple zones and each zone is defined as a group of zip codes. The Home Depot requires trucks to operate within zones to support the functionality of the MDO.

Project Objective

The objective of this project is to create a tool that will assess the fleet size of an MDO in the context of increased volume from new product channels being incorporated into the client’s MDO network. The tool also provides zip code to zone alignment charts that suggest which zip codes should be clustered together into zones and how many delivery trucks are needed to service that zone.

Design Strategy

The zoning tool will assess MDO fleet size by incorporating non-appliance products and explore impacts of blending them onto appliance trucks if these trucks have additional space. Additionally, a flexible zoning model will support MDO network expansion and address seasonal demand. There is an imperative to satisfy these objectives while also minimizing incurred costs, as current yearly costs for appliance and non-appliance trucks are at a ratio of 1.5:1, due to appliance trucks needing drivers that have appliance installation expertise. To investigate these opportunities, the team created mixed-integer programming (MIP) models to evaluate the impacts of a more frequent zoning cadence and the blending of product types. The first is a clustering model, which creates zones and assigns trucks based on the inputted demand file. A routing model is then used to validate the zones and truck assignments suggested by the zoning model. This design strategy was selected as it is a fast and repeatable process, ensuring that The Home Depot can rezone at any time for any MDO across the network.

Deliverables

From these objectives, the team has developed three main deliverables that will be presented to The Home Depot: a desk level procedure (DLP), a zoning optimization model, and a validation routing model. The DLP guides the user on how to use each tools created. The optimization model functions by minimizing the total weighted cost of trucks in a zone based on inputs such as demand, travel time, and the services each truck type is responsible for. This model creates a zone definition file and truck assignments for each zone. Additionally, the model features the ability to consider blending product types on a truck, as indicated by the user. The final deliverable is a routing model for the zone definitions that outputs a success metric for feasibility and utilization of the trucks servicing each zone.