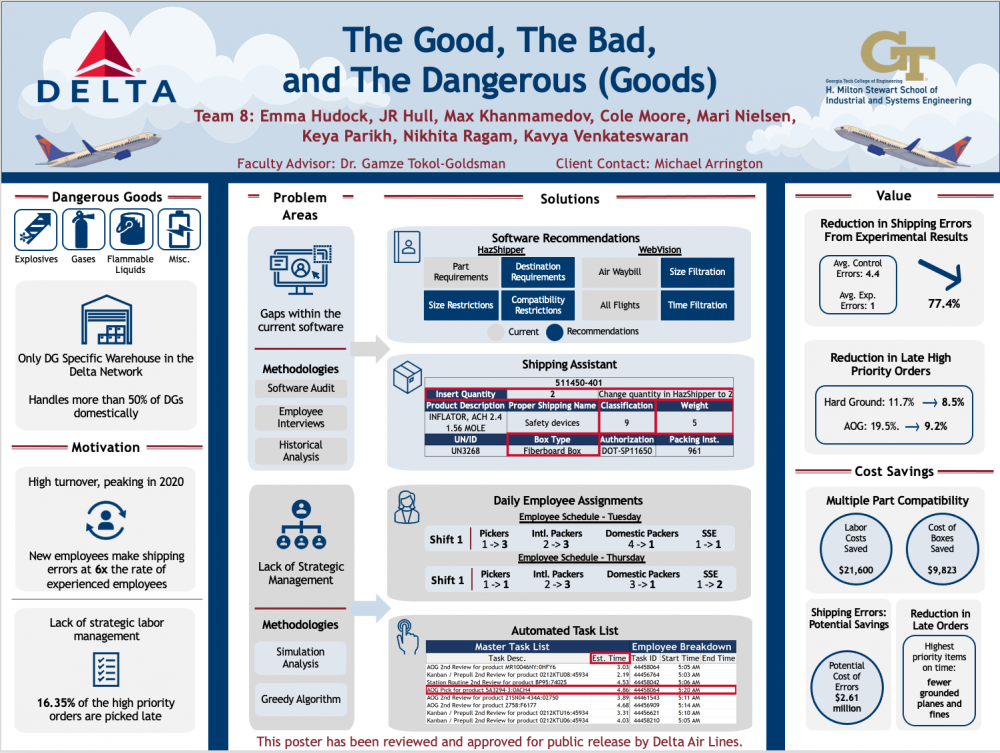

Client Context

Delta Air Lines is a major airline that runs over 4,000 flights per day across six continents, and each of their passenger aircrafts contain and ship items known as Dangerous Goods. A Dangerous Good (DG) is an item necessary for flight operations that fall under specialty classes such as explosives, gases, flammable liquids, etc. DGs pose an unreasonable risk to health, safety, and property when being transported and can only be handled by workers with special certifications and training. Examples of these items include life vests, oxygen masks, air conditioning panels, etc. While Delta handles 100% of its airborne DG transportation, the Atlanta DG Warehouse is the primary source of DG storage, maintenance, and shipment domestically and internationally. Additionally, the DG Warehouse is the only warehouse specifically dedicated to dangerous goods within the Delta network. Our team is focusing on the operations within the DG Warehouse, such as the putaways, picking, packing, and reviewing of DG items. The packaging of DGs can require specialty packaging materials, methods, and additional documentation.

Project Objective

The DG Warehouse initially expressed a need to handle the recent influx of new employees and related problems. Due to the pandemic, the DG warehouse experienced high turnover, peaking at 42% in 2020. With early retirements being the major factor for employees leaving, the overall experience level of the warehouse dropped. After analysis of the past two years, it became evident that new employees are six times more likely to commit shipping errors, showing a performance gap between experienced and inexperienced employees. This highlights a lack of comprehensive onboarding, training, and support for new employees. In conjunction with shipping errors, time targets for high priority orders were not being upheld. Hard Ground and AOG (Aircraft – on – Ground) orders were collectively picked late 16.35% of the time according to data from the past two years, emphasizing the lack of data-driven methodology behind labor management for employees within the warehouse.

Design Strategy

Over one hundred and twelve hours of site visits, the team observed variations in the order and manner of DG packaging, specifically as employees drifted from rote instructions in software and packaged DGs based on prior experience. New employees, however, followed steps in Haz-Shipper unless a packaging requirement is not addressed, in which case they seek guidance from experienced employees. This information gap prompted the team to provide a tool, the Shipping Process Information Document (SPID) to help all employees, and specifically new employees, pack complex shipments based on standardized information. After creating the SPID, the team experimented with the warehouse employees to validate the tool's effectiveness. With 4 scenarios, a control and experimental group of employees walked through the packaging steps and were graded on a set rubric. The team saw an error reduction of 77.6% when employees used the SPID. With the SPID available to employees, all employees in the warehouse could be tasked with simple to complex orders. To ensure that employees were completing the necessary tasks to uphold order priority, the team used simulation to provide a role breakdown by shift and day. The simulation was validated against historical data and through replicate analysis. Lastly, the team created a greedy algorithm to implement the role breakdowns and automated labor management within the warehouse. This was validated through a python package called SimPy which allowed the team to feed historical data into the algorithm and assign and collect completion time for each task.

Deliverables

Deliverable #1 – Business Requirement Document (BRD)

The BRD provides Delta with information gaps in their shipping software that disproportionately affect new employees. Additionally, it includes recommendations for features and information to add to Haz-Shipper and WebVision, along with other options and information for other software tools.

Deliverable #2 – Shipping Process Information Document (SPID)

The Shipping Process Information Document (SPID) combines existing information in Haz-Shipper and WebVision with the missing information identified in the software audit into a singular Excel resource. This document helps all employees, but specifically new employees, complete complex and international orders correctly. The resource contains three sections:

- Part Information: Employees can filter by part number to see the existing Haz-Shipper packaging instructions populate. Employees can also adjust the order quantity, automatically updating the shipment weight and removing the need for manual weight calculations.

- Destination-Specific Information: The SPID populates destination-related information for international destinations with the most complex additional shipping requirements.

- Multiple Part Compatibility Check: Employees can enter multiple different part numbers and the SPID automatically determines whether the parts are compatible, decreasing the likelihood of errors compared to manually checking part compatibility.

Deliverable #3 – Employee Role Designation Table (ERDT)

The Employee Role Designation Table (ERDT) provides optimal shift breakdown numbers to prevent delayed order fulfillment. Through simulation analysis and optimization tools, the ERDT breaks down the number of employees that should be in each role for each shift. This provides the Warehouse Supervisor with the ability to designate employees to a certain role within the warehouse. The team worked with the current employee availability to give breakdowns for each shift each day of the week.

Deliverable #4 – Labor Management Interface (LMI)

The team created the Labor Management Interface (LMI), an Excel dashboard that displays employees’ current task assignments, and its backend logic is a greedy algorithm. To provide the Warehouse Supervisor with an automated way to implement the role assignments listed in the ERDT, the LMI uses a greedy algorithm to assign priority scores to tasks and distribute them to available employees to uphold order priorities and time targets.

Value and Impact

Box Savings

The SPID allows the DG warehouse to implement multiple part compatibility. Using the compatibility table and historical order data, the probability any two DG parts are compatible for shipment is 78.13%. To obtain a conservative estimate, no more than two parts were grouped together. Based on these pairings, the team calculated an average of 8 boxes saved per day, amounting to total box cost savings of $9823 per year.

Labor Savings

As mentioned previously, our deliverables enable employees to package 8 less shipments per day. As packaging a shipment takes 15.74 minutes on average, the overall labor costs saved per year are $21,555.

Shipping Error Reduction

The experimental validation of the SPID resulted in a 77.4% reduction in shipping errors when using the SPID as an additional resource to the shipping process. In 2022 and 2023, the DG warehouse made 67 and 54 errors respectively, consisting of the five error types prevented by the SPID. The SPID’s 77.4% reduction in errors would have saved 52 errors in 2022 and 42 in 2023. Averaging these two years, the SPID will save Delta around $5,200 per year through direct error prevention.

High Priority Lateness Reduction

The ERDT and LMI’s reduction of late Hard Grounds and AOGs could save Delta between $50 thousand and $280 thousand per year by avoiding grounding of planes. Using the breakdown from the ERDT in simulations, delayed picks for Hard Grounds and AOGs decreased by 26.5% and 96.0% respectively.