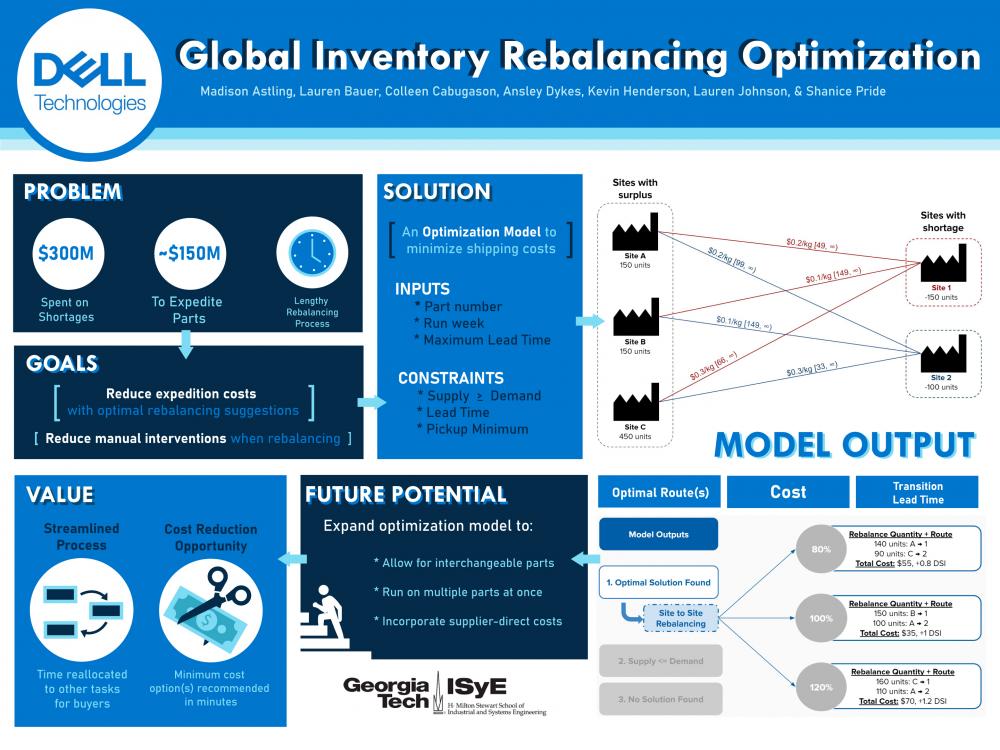

Client Context

Dell Technologies is a global computer software and hardware manufacturing company. This project specifically pertains to the Data Analytics and Automation group, which is within the company’s Global Operations department and overlooks the global supply chain of Dell’s products and services. The team is particularly concerned with using a data-driven approach to manage inventory and ensure that raw material parts are supplied to manufacturing sites efficiently.

Dell’s Global Supply Managers (GSMs) are responsible for the procurement of parts used to assemble finished goods to be sold to a consumer.. GSMs utilize forecasted demand data and reported inventory levels at each site to decide the number of parts needed per fiscal week. The initial orders for each fiscal week are placed far in advance, and the average lead time for these orders is about eight weeks. If the projected real demand exceeds the forecast, a shortage may occur. If a shortage is projected to occur, GSMs have two options: 1) Transition inventory from another Dell site with a surplus OR 2) Expedite additional orders of parts from a third-party supplier.

Moving inventory between Dell sites incurs only site-to-site transportation costs and reduces aging inventory across the supply chain. Expediting parts from a supplier adds the costs of new inventory being ordered, transportation, and additional expedition fees. Ordering from another Dell site is usually more cost-effective but could take longer to execute the transition of parts, whereas expediting from a supplier is usually faster but is often more expensive. The GSM must consider these factors during the decision-making process, while also factoring in the total cost, part availability, lead time, and routes available to remediate shortages.

The decision-making process for shortage resolution is manual and dependent on GSM intuition. Due to the lack of data driving these decisions, the rebalancing process is time consuming and susceptible to error.

While all subsets of parts are considered for site-to-site rebalancing, this project is only considering Desktop Structural (DT) parts as a sample population of all build-to-order (BTO) parts. This subset was selected because this type of inventory is regularly kept on hand at Dell sites and is a fair representation of most parts and their constraints.

Project Objective

Dell’s business is heavily impacted by part shortages. Currently, Dell has $300 million worth of revenue on hold across all products due to inventory shortages. Optimizing the shortage resolution process at Dell has the opportunity to improve the current system via:

- Cost Reduction: Around $150 million was spent on shortages resolved by expediting parts from the supplier in 2020. Since expediting from a supplier is almost always more expensive than site-to-site rebalancing, a reduction in supplier direct orders would equate to a reduction in cost. The solution provided to the client will identify the most cost-effective rebalancing option -- which is often not obvious to the GSM -- and has the potential to reduce total costs.

- Time Savings: Shortage resolution analysis and remediation takes up approximately 20% of GSM’s time, which is about 8 hours per week. When a shortage occurs for a part, the GSMs must manually perform a cost analysis to identify the best approach to remedy the shortage, whether that be moving inventory from another site or expediting directly from the supplier. The solution will automate the rebalancing analysis so that the overall time dedicated to the ordering process is reduced, freeing up time for other supply chain management tasks.

Design Strategy

We approached the problem by building an optimization model that would recommend minimum cost options and offer a more data driven approach. Our model is a mixed integer linear program with an objective of minimizing shipping costs when transitioning inventory. For the model to run, there are a few inputs required: the specific part, the week of shortage in question, and the longest lead time allowed to resolve the shortage. Once these are inputted, our model will output the optimal solution cost, routes, and lead time. The outputs are constrained by 3 main factors. The first is that the supply has to be greater than the demand, which, in our context, means the total surplus at sites have to be greater than the total shortages. The second constraint is the lead time that must be met. And the final constraint are the pickup minimums on some routes.

We validated the model using a step-wise approach to implement the model in a python script. This process began by creating a model that only included a subset of the constraints. Then, more complexities were added to the model and validated using the team’s manipulated input data.

Deliverables

This project has two final deliverables: a theoretical optimization model and a data-driven python script. The main purpose of the theoretical model is to explain the logic of the code to both technical and non-technical members of the client team. The theoretical model is also included for its expansion capabilities, allowing the client to incorporate additional constraints such as interchangeable parts or changes in route cost calculation. The python script implements the model with Gurobi optimization using flexible soft-coding. The output of the script translates the model into a context the GSM can understand.