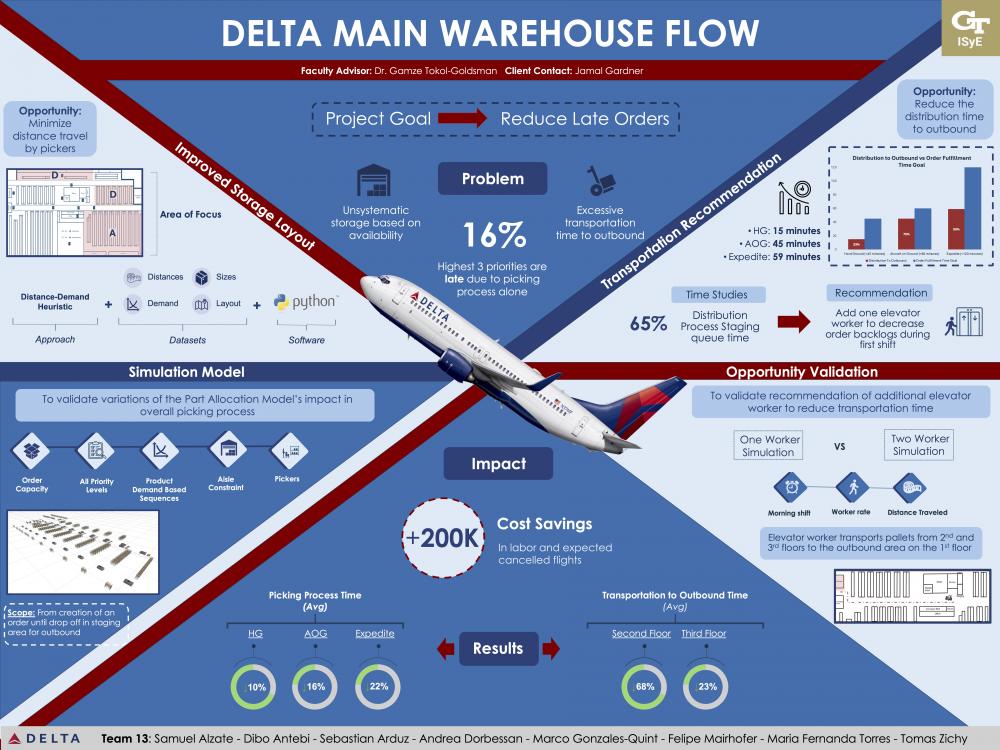

Client Context

Delta TechOps TOC2 is a 3-story warehouse located at Atlanta Hartsfield Jackson Airport, responsible for the storage, retrieval, and shipment of parts needed for maintenance of aircraft in both local and international locations. All inbound and outbound operations take place on the first floor, while manual storing and picking of maintenance parts on the second and third floors. All floors are connected through elevators. Maintenance parts are requested from TOC2 through an “order”, which is initially created in TOC2’s SAP system along with its priority. Then, parts within that order get manually picked on the second or third floors and an elevator worker transports it to the outbound area on the first floor where it gets inspected and shipped.

Project Objective

The senior design team aims to decrease the number of late orders for aircraft to reduce costs. Currently, Delta allocates parts across the warehouse based on availability. This causes pickers to frequently spend excessive time traveling to far-away storage locations to retrieve parts that are on high demand. This, along with the lengthy process of transporting picked orders via elevator from the second and third floors to the outbound area of the first floor, leads to longer delivery times.

Design Strategy

Analysis showed that 16% of the orders from the 3 highest priorities, which account for 80% of the total orders at TOC2, are not delivered on time from the picking process alone. This can be attributed to the unsystematic inventory allocation process. The team developed a Python model using a distance-demand heuristic that will swap parts in high demand in far-away locations with parts in lower demand in closer locations to reduce the distance traveled by pickers. The team also conducted time studies to analyze the time it takes to deliver something from the second and third floor to the first floor. It was all validated through multiple Simio models to ensure accuracy.

Deliverables

The new storage layout will be delivered with an Excel file showing each part number and new location. Along with the Excel file, the team will deliver a manual in which we will describe thoroughly how to run the code step by step in order to use this deliverable in the future. The team will also deliver a recommendation of adding an additional worker to help with transporting items to the first floor and speed up the process.

Value and Impact

The simulation model showed a 16% decrease in the time to complete the picking process on average across the three priorities, which estimates an economic impact of more than $195,000 in cost savings per year. As well as results showed that the parts’ time in system decreased by 68% and 23% from the second and third floors respectively.