Client Context

The On-Board Services (OBS) group within Delta Air Lines determines food and beverage items to load on each flight. Each flight offers customers a variety of food and beverages that changes based on class of service and flight distance. Select stations have catering kitchens that prepare, load, and deliver food, beverages, and single-use items onto the galley carts that flight attendants serve from. OBS sends a specification document to the catering facility that is servicing a particular flight, the kitchen fills the galley carts accordingly and delivers them to the aircraft. Upon the arrival of the aircraft’s final catered leg, the local catering kitchen brings the galley carts back to their kitchen, empties and cleans drawers, then refills the carts for their upcoming flights.

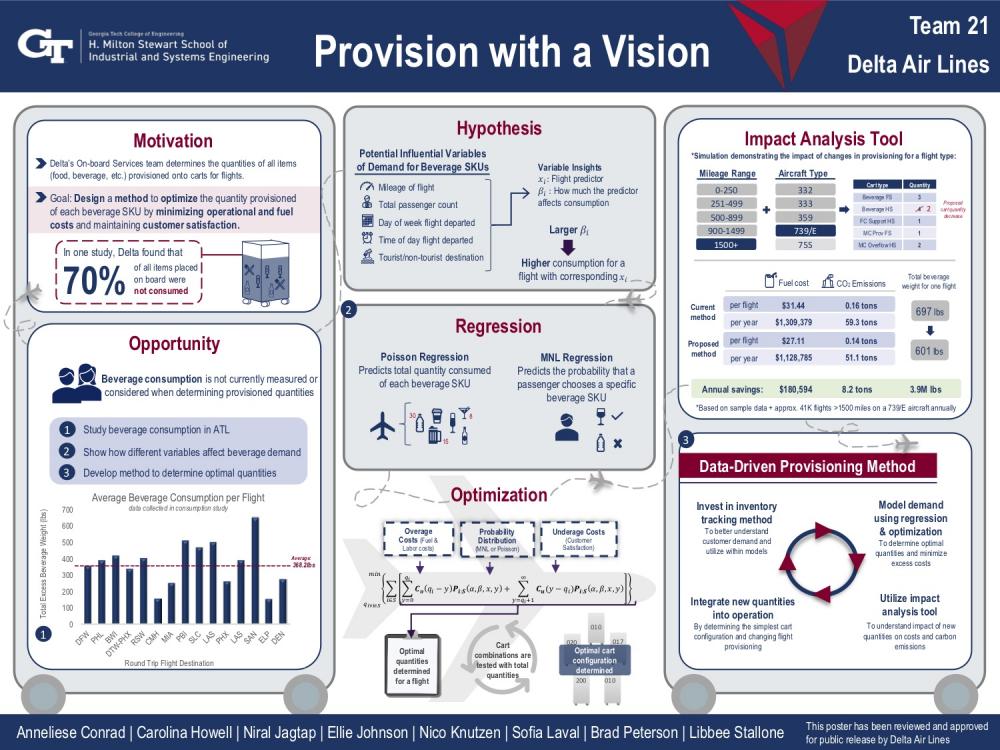

Project Objective

The primary problem is that OBS lacks insight into beverage demand, which results in overestimating the quantities put on flights. There is an excess of items being put on flights and flown around without getting consumed. The team has identified a source of this issue to be the lack of a data-driven provisioning method. Delta’s current decision-making system does not allow for quantities to be determined based on customer demand for each SKU per flight factors such as time of day and day of week. The consequences of this are seen in excess inventory and can be valued by the additional fuel costs resulting from excess weight being flown and labor costs resulting from unloading and restocking corresponding carts. The main opportunity is to develop a method for determining optimal quantities for each SKU to provision onto each flight, while considering hard and soft constraints. Additionally, a user-friendly tool would allow Delta to quantify the financial and environmental impact of making small changes in beverage quantities.

Design Strategy

The approach of this project is to design a method that outlines how to model demand and calculate optimal quantities. To build the framework, the team conducted an initial consumption study at the Atlanta domestic catering facility. Overall, the team collected consumption data for beverages from 15 flights over the span of six visits, totaling around 20 hours of collection time and flight kitchen observation. To estimate demand, the team utilizes Poisson and Multinomial Logistic (MNL) regression. Poisson models the total consumption of a beverage on a flight while MNL predicts the choices made between various alternatives. The team created hypotheses as to what factors affect demand such as time of day and destination type. From here, the demand distribution can be used to run the optimization model which takes into consideration the overage and underage costs of provisioning.

Deliverables

The final deliverable to Delta is a data-driven provisioning method that begins with further data collection based on the process used by the team. Both regression models are presented to the client, giving Delta the option to choose whichever best suits their system and data using cross validation. The optimization for SKU quantities can be implemented using TensorFlow Constrained Optimization in Python. The first step of the optimization model can be used to determine the optimal order quantities stocked on a particular flight. The second step of optimization is transforming the optimal beverage quantities into optimal cart configurations.