Client Context

Our team partnered with Novelis, the world’s largest flat-rolled aluminum producer, and recycler, to streamline and optimize the automotive sales team’s quoting and SKU assignment process.

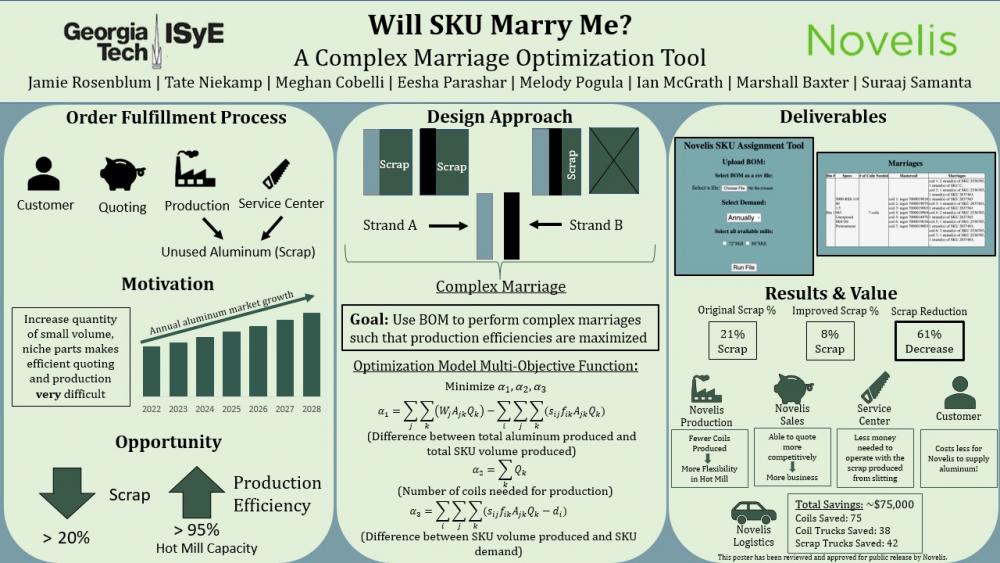

The production process begins when a client sends Novelis a forecast in the form of a bill of material (BOM). The BOM contains the annual demand of stock-keeping units (SKUs) for a specific vehicle type and SKU specifications such as dimensions, treatments, alloys, lubrications, surface qualities, and coatings. More specifically, SKUs are strands of aluminum cut from coils, which customers stamp onto aluminum vehicle parts. Novelis cuts SKUs from coils at two separate vendors based on their volume. Novelis cuts large-width, large-volume SKUs from coils at toll processors. Toll processors are third-party contract manufacturers employed by Novelis to cut SKUs from coils, but toll processors can only cut one SKU from one coil. Novelis cuts small-volume, small-width SKUs from coils at service centers. Service centers can be considered toll processors contracted by automotive OEMs instead of directly by Novelis. Service centers also can make multiple vertical cuts at their slitting lines and cut multiple SKUs from the same coil.

The Novelis sales team determines which SKUs Novelis cuts at toll processors and which are cut at service centers. Additionally, the sales team determines which small-volume SKUs can be cut from the same coil. The sales team determines which SKUs can be married by looking through the customer’s BOM and manually matching SKUs with shared specifications and similar volumes.

Project Objective

Novelis wants to reduce the scrap created in their production process, specifically, the scrap produced from the service centers. Excess scrap is indicative of excess master coil production, which means that Novelis is using more aluminum coils to fulfill an order than is necessary. These are significant issues for Novelis since their hot mills operate above capacity, and scrap can be very costly to transport.

The motivation for this project stems from increased customer demand for small-volume parts. As the volume of each SKU decreases, the number that can fit onto one coil increases, creating a substantial number of SKUs that can be paired on the same coil. Since Novelis is assigning SKUs to master coils by hand, there is no way for them to determine if their current combinations are minimizing aluminum scrap. To produce a result with the optimal amount of scrap and number of coils produced requires an optimization software.

The team identified an opportunity to implement an optimization tool to identify the number of coils needed to fulfill customer demand and the amount of scrap produced by the recommendation.

Design Strategy

After understanding how the slitting lines work in the service centers, we determined that the solution to assigning these complex marriages could be modeled as a variation of a one-dimensional cutting stock problem. The first step in the design was determining which SKUs were to be cut in the service centers and which were to be cut in the toll processors. This process reflects the current decision-making technique, where the SKUs that require an average demand greater than 1 coil per month should be cut at the toll processors and the rest should be cut at the service centers. Those that are sent to the service centers are categorized into bins that share similar specifications, since only SKUs with certain same specifications can be paired together. These bins are run through the bin packing optimization model with the multi-objective function of minimizing scrap produced, the number of coils produced, and the difference between the SKU volume produced and the SKU demand specified on the bill of materials. The results of the model are output into CSV files for the Novelis team to reference. Our team tested the results of our model by comparing them to the manual results done in the previous year. We compared the scrap percentages between the models and made sure that the bins that were created manually matched the bins created in our model.

Deliverables

To automate and optimize the complex marriage process, we created a multi-objective Gurobi optimization model based on variants of one-dimensional cutting stock problems and bin packing problems. The three objective functions are weighted equally, with the first minimizing the amount of scrap, the second minimizing the number of coils produced, and the third decreasing the amount of excess material on a strand being sent to a customer. The objectives are weighted equally because that is what yielded the best results. We then integrated the model with an HTML User Interface using Flask in Python to allow the user to input a Bill of Materials, choose a demand period, and run the model. The UI then outputs a CSV file with a table of the bins, a bin being a list of SKUs with matching specifications, of the scrap analysis, and of all the marriages. The sales team can then use this information to aid in their quoting process, and the production planning team can use this in their planning process. m

Value and Impact

The team compared the model's results with a manually quoted 2022 General Motors (GM) bill of materials and found a 61% scrap reduction when using the tool. This reduction results in approximately 75 fewer coils needed to fulfill the same demand, 38 fewer trucks transporting coils to service centers, and 42 fewer trucks needed to transport scrap back to the Oswego remelt facility. In total, there are approximately $1.2 million in production and logistic cost savings that will be experienced until the Novelis sales team fills the freed-up capacity created by the tool. Novelis consistently operates its facilities on volume thresholds and plans to use the freed-up capacity to take on additional customer orders that the company previously rejected due to production constraints at its facilities. Once this demand is met with those saved coils, Novelis will experience an increase in market share gains of approximately $2.1M. The team was able to scale across GM programs due to the similarity of parts and scrap percentages in their orders. GM represents less than 5% of Novelis’ automotive demand, so there are significant additional opportunities for production and logistics cost savings.

With the tool’s ability to quickly produce results and a scrap analysis, the Novelis sales team can produce quotes faster, and the customer will have increased transparency in the quoting process where the Novelis sales team can use it in their quoting discussions. They can show the customer how they can consolidate constraints so that more SKUs share the same specifications allowing more complex marriages to be performed thus decreasing the scrap percentage for the order even further.