Client Context

Cisco Systems Inc. is a multinational corporation headquartered in San Jose, California founded in 1984. It has since become the leading manufacturer in the computer networking industry with more than 74,200 employees in over 115 countries. Cisco develops, manufactures, and sells networking technology such as modems, switches, and routers. The company also assists their customers by providing consulting and data management services.

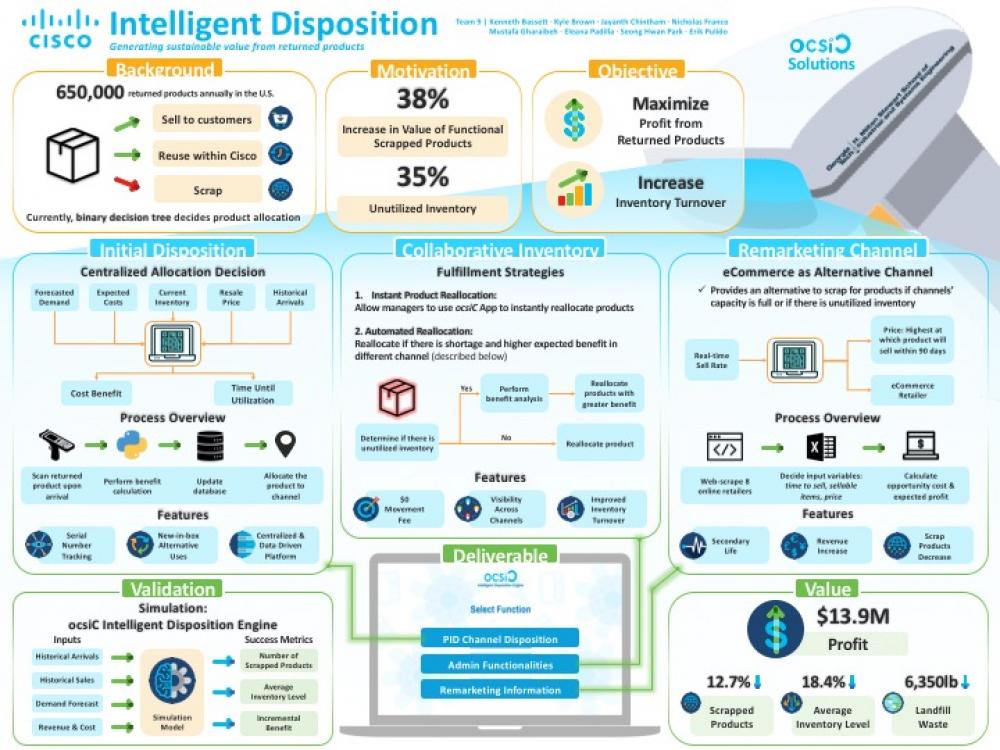

Current System: The project focuses on Cisco’s North America Reverse Logistics operations, is driven by over 650,000 annual customer returns, and all products are received in one facility in Roseville, California. After receiving a product and determining the condition, the current process (Dynamic Disposition) determines how products are allocated to channels. Each channel refers to the different end uses for products. Each channel has the opportunity to request a product by specifying preferred product condition and how urgently they need the product. By processing the requests made by each channel, the current system determines where to send products.

Products can be scrapped in two scenarios: (1) when a product is not requested by any channel, or (2) when inventory capacity is full. Both scenarios are referred to as auto-scrapping. Approximately once per quarter, each channel’s inventory is manually examined to identify products that have been in inventory for over 180 days and considers these products for scrapping. This method of scrapping products is called purge-scrapping.

Once a product is allocated to a channel, the product is placed in that channel’s inventory, and that channel assumes ownership of the product. Products that are allocated to be resold as new are shipped off-site, back to Cisco’s manufacturing facilities, while all other channels’ inventories are held within Cisco’s warehouse. Inventories are separately held, in the same warehouse, but channels do not have visibility into other channels’ inventories. Channels are only able to collaborate if one channel manually starts an email exchange with another channel stating they have a need for a product; this process is not common.

Project Objective

In 2018, Cisco put forth an initiative to contribute to the $4.5T circular economy, focused on reducing overall consumption of energy and materials by recovering 100% of their sold hardware through returns. As Cisco receives returned products, they must decide whether to allocate them to a distribution channel to find a secondary use or scrap them. During fiscal year 2019 (FY19), Cisco’s Reverse Logistics operations received more than 650,000 products in North America alone. However, the value of working-condition products that were scrapped increased by an average of 38% per quarter during FY19. In total, $36M worth of working units were scrapped during FY19. This presents an opportunity to find more efficient, profit-generating ways to make use of Cisco’s vast Reverse Logistics presence.

Design Strategy

The goal of this project is to maximize the benefit received from returned products. This is achieved through three key steps: (1) introducing a new mathematical model to allocate products to channels based on expected profit, (2) consolidating inventory to reduce labor costs from physical movement of products, creating a model to facilitate reallocation of inventory between channels, and (3) enabling e-commerce retailers as alternative remarketing channels.

The following four steps were followed throughout the semester to produce the final deliverables:

Analyze the current system to determine areas where value is being lost

Design solutions to maximize the value of returned products

Recreate current system to back-test each improvement through simulation models

Develop strategies to implement solutions into Cisco’s operations

To validate the impact of the three improvements, Python simulation models were created to replicate the current system and test each improvement. Each simulation model processes Cisco’s FY19 data on arrivals, forecasted demand for each channel, and sales from each channel. Over 500,000 arrivals are processed by each simulation, representing 80% of the system’s FY19 volume in terms of products received. Finally, an expected revenue and cost table was created using Cisco’s data per PID. Data was organized in an SQLite database and used as input to the simulation.

The effectiveness of each solution was evaluated based on three metrics: (1) benefit, (2) reduction of scrapped products, (3) average inventory levels. Benefit is the sum of the revenue from all sales made while subtracting all costs incurred. Reduction of scrapped products is the percent change (from the current system) of products that are scrapped. Inventory levels are monitored by calculating the average daily inventory across all channels throughout the year.

Deliverables

ocsiC Intelligent Disposition Engine GUI:

The Intelligent Disposition Engine incorporates each improvement in a stand-alone web-based application. The application is designed specifically for warehouse employees, and administrators, such as channel managers, and has been engineered for efficient integration into Cisco’s systems. By connecting to Cisco’s servers, it would allow any user to remotely connect to the application within Cisco’s internal network.

ocsiC Intelligent Disposition Engine Logic:

To easily integrate Intelligent Disposition into Cisco’s current operations, a PDF write-up was created providing all of the formulas, logic, and assumptions made in the development of Intelligent Disposition.

Remarketing Scape Tool:

A python script has been developed to allow Cisco to gather and store data for Cisco products from six different online retailers by simply inputting a keyword (Cisco product ID). The tool can be used on a stand-alone basis, or as part of the GUI.

Simulation Code & Results:

The codes used to perform five different simulation scenarios were sent to Cisco, as well as the database output files used to develop the value of the project. These files allow Cisco to understand, on a product by product basis, how the performance of their current system’s logic could be improved by the implementation of Intelligent Disposition.