Client Context

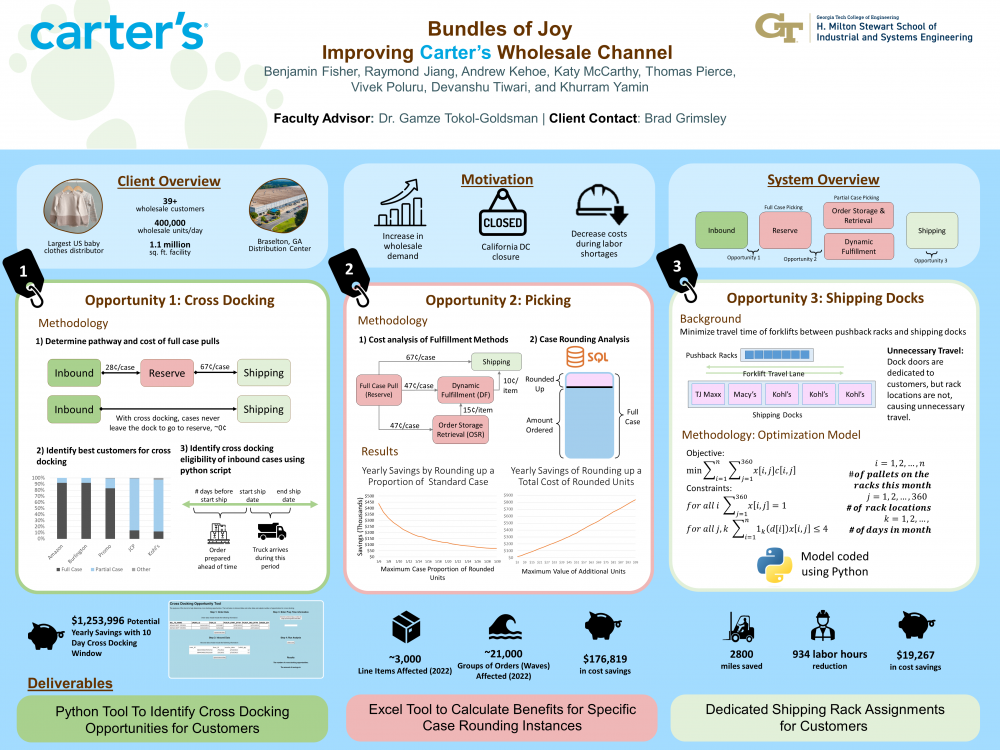

Carter’s is one of the largest baby and children’s apparel companies in the world, processing items for wholesale, retail, and e-commerce channels. Carter’s Braselton DC recently acquired wholesale customer demand previously fulfilled by Carter’s Chino, CA facility which closed last year. New wholesale customers included high-volume vendors such as Amazon, Macy’s, and JCPenney. Braselton DC’s wholesale throughput is expected to grow from 127,083 units per day in 2022 to 162,670 units per day in 2023. When wholesale inventory and demand spiked in September and October of 2022, Carter’s saw symptoms of a stressed wholesale system such as delayed and canceled orders paired with congestion at the dock doors. The warehouse also faces labor shortages, particularly with forklift operators.

Project Objective

The team analyzed the wholesale system, from processing to shipping, to provide Carter’s with recommendations that reduce costs and enable capacity to handle increased demand. The team identified areas of improvement through the investigation of order and customer profiles, process costs, and wholesale process touchpoints. This project aims to streamline system flows and reduce labor costs.

Design Strategy

The team qualitatively researched the system through several tours in the warehouse, interviews with employees (e.g. waving team, wholesale process managers, industrial engineers). The team quantitatively analyzed process flows (touchpoints, costs) in the warehouse for different wholesale orders to determine areas of improvement. Additionally, the team researched customer profiles within the wholesale channel to determine what system changes might have the largest impact. The team identified different ways, from inbound case processing to shipping, to minimize cost. Historical data from 2022 and early 2023, SOPs, warehouse layouts and more was provided by Carter’s and used to understand customer order profiles and current warehouse operations.

Deliverables

The team proposed the implementation of cross docking, a system change that would allow inbound cases to be routed directly to outbound docks to satisfy demand. The team identified cost of implementation and potential savings for major customers ordering in inbound case quantities. Additionally, a python GUI was developed to allow Carter’s to continue researching opportunities for cross docking for other customers’ orders. Second, the team provided analytical findings for case rounding to the customer. Orders could be rounded to a full case to skip the costly partial case picking steps. The deliverable contains an excel tool detailing the savings from a particular instance of case rounding and two graphs describing the overall savings from a given proportion on case rounding. The deliverable will help Carter’s negotiate and encourage case rounding strategies with their customers. Lastly, the team recommends customer-dedicated, but flexible pushback rack locations for pending shipments. The team provided Carter’s with a data set and corresponding Python optimization script indicating the appropriate rack assignments for each customer.

Value and Impact

Through cross docking, the team found 47% of all inbound inventory has the potential for cross docking (using a 10 – 21-day prep window), resulting in $1,253,996 of potential annual net savings. Through case rounding, assuming 1/15 of a full case is an average rounding metric for customers, the team found that $176,819 can be saved by avoiding the partial case picking system. Through a dedicated pushback rack system, the team found $19,267 can be saved by having customer specific locations. Furthermore, the team expects additional benefits such as a reduction in lost pallets.