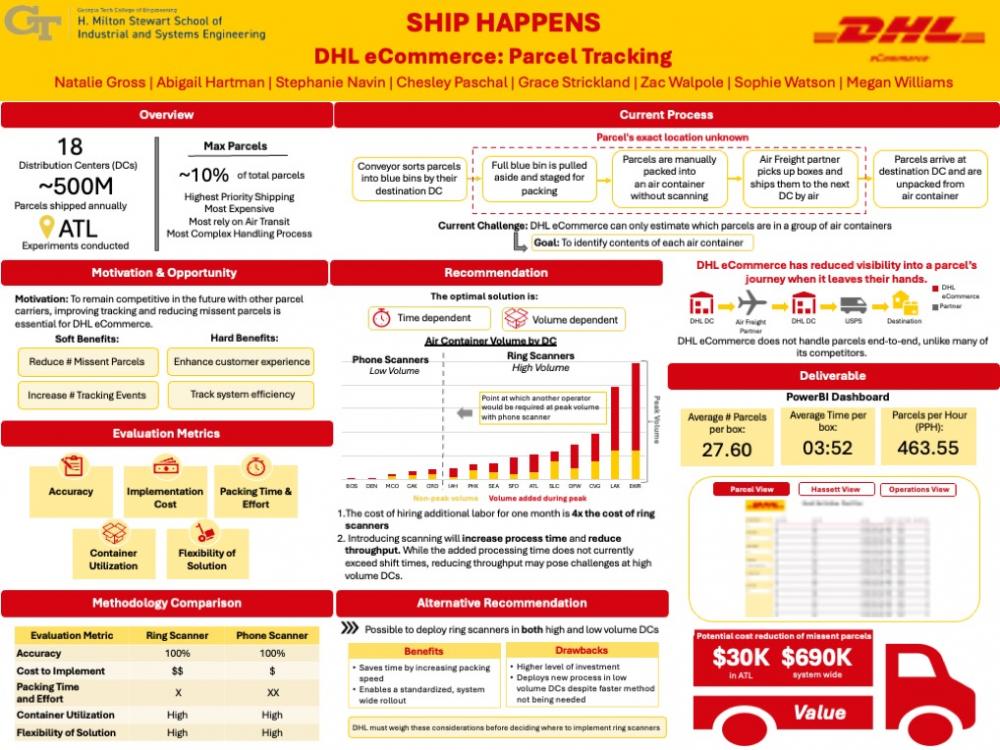

Client Context

DHL eCommerce (DHL) provides parcel delivery services for online businesses and operates through a network of 18 distribution centers (DCs) in the US. A key aspect of how DHL operates is through partnerships. DHL leverages partners to handle certain steps in their shipping process: a partner handles air freight between DCs, and another partner handles local delivery to the final destination. Because of this, DHL has reduced visibility into a parcel’s journey when it leaves their hands. This distinguishes DHL from many of its competitors, who operate end-to-end, offering them more visibility into a parcel’s journey than DHL. This project focuses on the visibility gap in the outbound handling process at a parcel’s origin facility, specifically with Max parcels. Max parcels account for around 10 to 15 percent of DHL’s volume. Max parcels are DHL’s highest priority shipping service, are the most expensive product to handle, and heavily rely on air transit to ensure fast delivery. Most importantly, Max parcels have the most complex handling process.

Project Objective

In the air transit packing process, the challenge manifests once a parcel has been sorted by their destination DC into a large "blue bin", which then has to be packed into multiple smaller boxes for air transportation. There are two challenges here: DHL does not know what parcels are in a blue bin and DHL does not know what parcels are in an air transportation container. Once a parcel lands in a blue bin, DHL cannot pinpoint the exact location of an individual parcel until it arrives and is processed at its next DC. Ultimately, this impedes DHL’s ability to identify and address delays, which is critical for Max parcels as the fastest shipping service. The goal of this project is to allow DHL to identify the contents of an air transportation container by scanning parcels into the air transportation container in the most effective and efficient way possible. This encompasses being able to answer three key questions:

- Where is a parcel?

- What are the contents of an air transportation container?

- How is performance at an operator, DC, and network wide level?

Design Strategy

The team designed and conducted multiple experiments in the Atlanta DC to determine the best method for implementing a scanning process for air transportation container packing. The team determined evaluation metrics for the experiments that were used to guide the recommendations presented to DHL: accuracy, implementation cost, packing time and effort, container utilization, and flexibility of solution. During our team’s experimentation, we packed 2,590 parcels into 79 air transportation containers. We tested different combinations of system changes, scanning frequencies, and scanning technologies to see the effect each had on speed, accuracy, labor, and overall usability.

We tested a minimal and maximum scan frequency when packing the air transportation containers. The data collected from these experiments showed that the core tradeoff between the two methods is accuracy and timing. We found that maximum scanning provided near-perfect accuracy and therefore was able to catch missorted parcels before they left the DC. However, it increased packing time by 33% and slowed operators down, so for maximum scan to be realistic across the network, we needed to explore ways to reduce scan time per parcel through faster technology or a more ergonomic workflow. The minimal scanning allowed operators to maintain a packing speed close to no scanning, but the accuracy was only 42% because machine sort order was heavily disrupted in the blue bins.

Therefore, to make the minimum scan method viable, the team explored system changes to better preserve sort order without increasing time. These findings guided the next few phases of our work. We then tested design changes to maintain sort order of parcels, and from these experiments, we concluded that we were able to significantly increase our accuracy to 90%. But the slides would not be feasible within our system as they are expensive and an inflexible option. They must be permanently installed on each outbound line and cannot easily adapt to different DC layouts or volume levels. Additionally, since operators are not scanning every parcel, they will not catch missorts.

Finally, we compared three different scanning devices: phone scanners (currently in use), ring scanners, and an overhead scanner. We determined that either ring scanners or phone scanners while scanning every parcel into the air transportation container would be two potential solutions.

Deliverables

Deliverable #1: Recommendations for Scanning Implementation

Our recommendation depends on the volume and time available for air transportation packing at the DC. These containers are picked up each shift, so any Max parcels not packed by the deadline will be left and delayed. The recommendation is volume dependent because phone scanners are already available in DCs, so the volume must require a faster scanning method to justify the additional cost of ring scanners. We compared the volume capacity of phone scanning and ring scanning in each DC based on the estimated amount of labor available and the time limit for packing air transportation containers. Volume above a designated cut-off would require hiring an additional operator to continue using phone scanners. The cost of hiring an additional operator for just one month is much higher the cost of investing in ring scanners. Therefore, even if a DC’s volume only exceeds this cutoff during peak season, we still recommend investing in ring scanners.

Our recommended solution is:

- Use phone scanners at low-volume DCs: those handling at below the volume cutoff at peak season

- Invest in ring scanners at the remaining high volume DCs.

Alternatively, DHL could implement ring scanners across all DCs. Although this would require a larger investment, it would allow every DC to have a consistent workflow. Additionally, ring scanners have a higher throughput, so low volume DCs could pack containers faster and potentially save labor costs. DCs hire additional labor during peak season, but if low volume DCs used ring scanners, they would not need to hire as much additional labor. DHL can evaluate if they could save enough costs by reducing peak season hiring or reducing or reallocating labor throughout the year to offset the cost of implementing ring scanners. DHL can use our financial model to help them evaluate this alternative recommendation.

Deliverable #2: Financial Model

An Excel financial analysis model will be given to DHL so they can evaluate missent parcel savings and NPV for all DCs. They will be able to adjust values such as hourly wages, parcels per shift, cost per missent parcel, missent parcel rate, and air transportation container cost. The model will easily compare the revenues and costs of the five solutions, so DHL can implement the best one for each DC.

Deliverable #3: Power BI Dashboard

To address the question of “what is in an air transportation container” and to bring visibility into the packing process, our team has developed a Power BI (PBI) dashboard with 3 view. Within this dashboard, packing time per container, parcel count per container, and parcels per hour (throughput) are established as the KPI’s used to measure the efficiency of the packing process.

In the first view, the “Parcel View,” DHL will be able to pinpoint the air transportation container each parcel is in, along with the operator, destination DC, scan time/date, and origin DC. This will be beneficial for DHL if a parcel gets lost because they will be able to look up the barcode to determine if or when the parcel was scanned and staged for pickup to narrow down its location. Or if a container gets lost, DHL will now be able to know for certain what parcels were lost within it.

In the “Air Transportation Container View,” DHL gains visibility into container level insights, including the packing time and parcel count for each container, the operator, scan time/date, and origin DC. This view displays overall KPIs, including average parcel count per container, average packing time per container, throughput, and total parcels packed. This view allows DHL to monitor and evaluate the efficiency of the air transportation container packing process.

Lastly, the “Operation View” also provides DHL with clear insights into the packing process, but with the data broken down into the operator, origin DC, destination DC, or any combination thereof. This enables DHL to compare performance across relevant factors to determine where it operates the most efficiently, for best practice identification, and where more training is necessary.

Value and Impact

The project benefits fall into two categories: ‘hard’ benefits, which are those that have easily quantifiable value, and ‘soft’ benefits, which are less quantifiable but progress DHL towards larger organizational goals.

The most relevant hard benefit of this project is being able to reduce missent parcels and thereby any associated costs. Sending a parcel to the incorrect DC or missing deadlines for Max parcels outlined in Service Level Agreements (SLAs), incurs costs for DHL because of the additional shipping and handling required to remedy the situation. Being able to identify air transported contents accurately would reduce missends as a byproduct and help to avoid costly errors. We estimate that this could save DHL $690,000 across the network annually. Another hard benefit is an increase in the number of tracking events. This creates more datapoints on a parcel’s journey and provides additional visibility into the status of customer packages, allowing DHL to better align with industry standards.

Additionally, DHL will derive soft benefits, such as enhanced customer experience and improved tracking of its systems and performance levels. DHL’s partners and customers increasingly demand more visibility into its handling processes, and it is critical to maintain and expand their business while remaining at a competitive price point. Additionally, being able to specifically track elements of system efficiency across DCs, shifts, and individual operators will allow DHL to improve their handling of the Max product.