Client Context

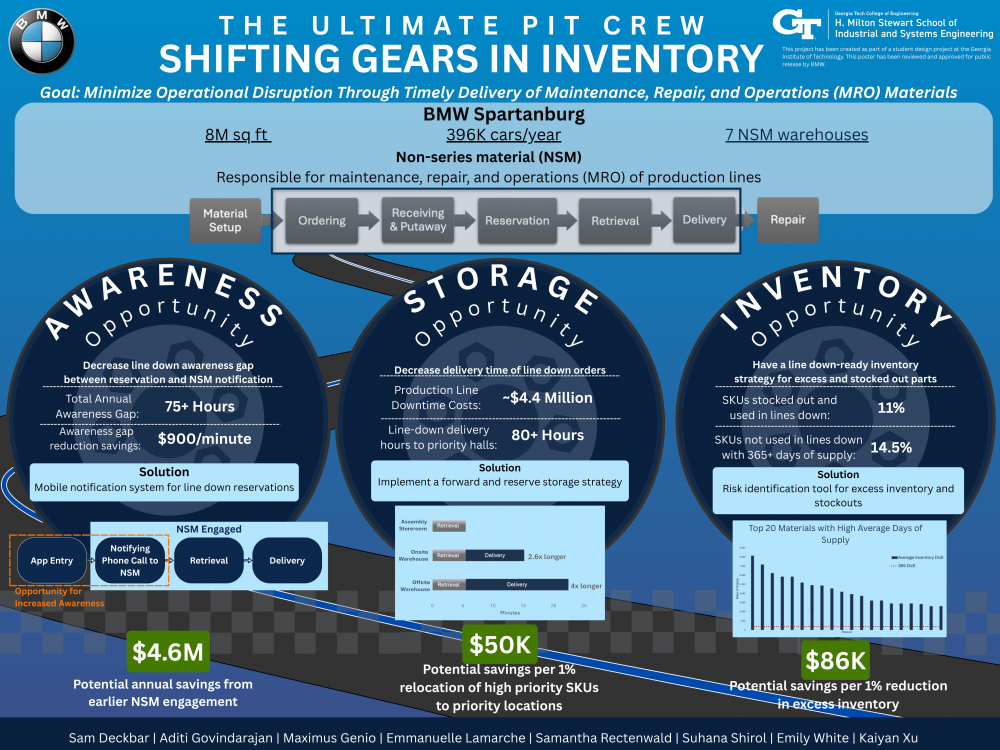

Bayerische Motoren Werke AG (BMW) is a global luxury vehicle manufacturer based in Germany. Its largest plant in Spartanburg, South Carolina produces almost 400,000 cars per year. Our client, the Non-Series Materials team (NSM), is a non-production line group responsible for inventory management, retrieval, and delivery of parts for the maintenance, repair, and operation (MRO) of production line equipment. The NSM team delivers parts to service and repair equipment in the Body, Assembly, and Paint production line groups when equipment on these production lines fail or require scheduled maintenance. Production line downtime is valued at $900 per minute, so the Non-Series Materials team prioritizes the delivery of parts for these repairs. NSM’s overarching mission is to minimize operational disruption on the car production lines through timely delivery of maintenance and repair parts.

Project Objective

Our project objective was to help our client get MRO parts to the production lines faster, in order to reduce the costs associated with lines down. We addressed this in three different ways:

- Reducing the line down awareness gap between production lines and the NSM team

- Storing parts in locations that decrease delivery times for line down orders

- Improving BMW's inventory reordering strategy to be more line down ready

Design Strategy

The line down awareness gap comes from the time between when an urgent reservation is created in BMW's mobile reservation app by a production line associate and when the NSM associate is notified of the reservation by a phone call from the production line. We analyzed their current processes and systems to determine feasible ways to reduce the awareness gap that we identified.

Next, to decrease delivery times for line down orders, we determined that high priority parts should be placed as close to their production line group users as possible. After identifying that our client often faces storage space reallocations, we decided to design a tool that could be used to determine what should be moved during these iterative reallocations. We developed an aggregate optimization model in python to determine the most optimal storage locations for different categories of parts and their corresponding storage types. Balancing space constraints, as well as line down delivery times for different parts, we determined that a forward and reserve storage system would allow for more unique parts to be placed in the higher priority locations, with shorter delivery times.

Finally, there are two components of the NSM team's inventory ordering process that pose a risk to production operations. Excess inventory can lead to limited available storage space in locations with shorter reservation fulfillment times. Stockouts risk parts being depleted entirely during a line down situation. For our last deliverable, our methodology is structured around two complementary analyses: excess inventory identification and stockout risk assessment.

Deliverables

Our first deliverable that we have provided our client with are recommendations for a notification system that informs the NSM team of line down reservations before a phone call is made. We provided four different potential options to ensure feasibility within BMW’s operational and IT constraints

Our second deliverable is a storage planning optimization model that aims to decrease delivery times for line down reservations by placing high priority parts in priority locations and near their users using a forward and reserve storage strategy. We provided this tool through Streamlit, which makes it easy for our client to upload files, adjust different parameters, and add/delete storage locations.

Our third deliverable is a Streamlit tool to identify parts with excess inventory and parts that have a high risk of being stocked out to provide the NSM team enhanced visibility to parts that pose a risk to the car production operation. It enables the NSM team to upload updated data and instantly view prime candidates for ROP adjustments. The tool can be used periodically or on an ad hoc basis depending on the team’s needs.

Value and Impact

For our first deliverable, the time savings from our recommendation to reduce the line down awareness gap could translate to a potential $4 million in avoided operational disruption costs.

For our second deliverable, we identified that for every 1% increase in the allocation of high-priority parts to locations closer to their respective users, there is an estimated $50,000 in potential annual savings due to reduced line down fulfillment time.

For our third deliverable, we found that for each 1% reduction of excess inventory, $86,000 could potentially be saved in inventory costs.