Client Context

Wellstar Health Systems is one of Georgia’s largest healthcare providers, with Kennestone Hospital in Kennesaw serving as a Level I Trauma Center. This project focuses on the PeriOperative Services within Kennestone, which encompasses all medical attention provided to a patient before, during, and after a surgery. Some key operations for this division include: Surgical Supply Management, Preference Card Creation and Maintenance, and Post-Procedure Supply Maintenance.

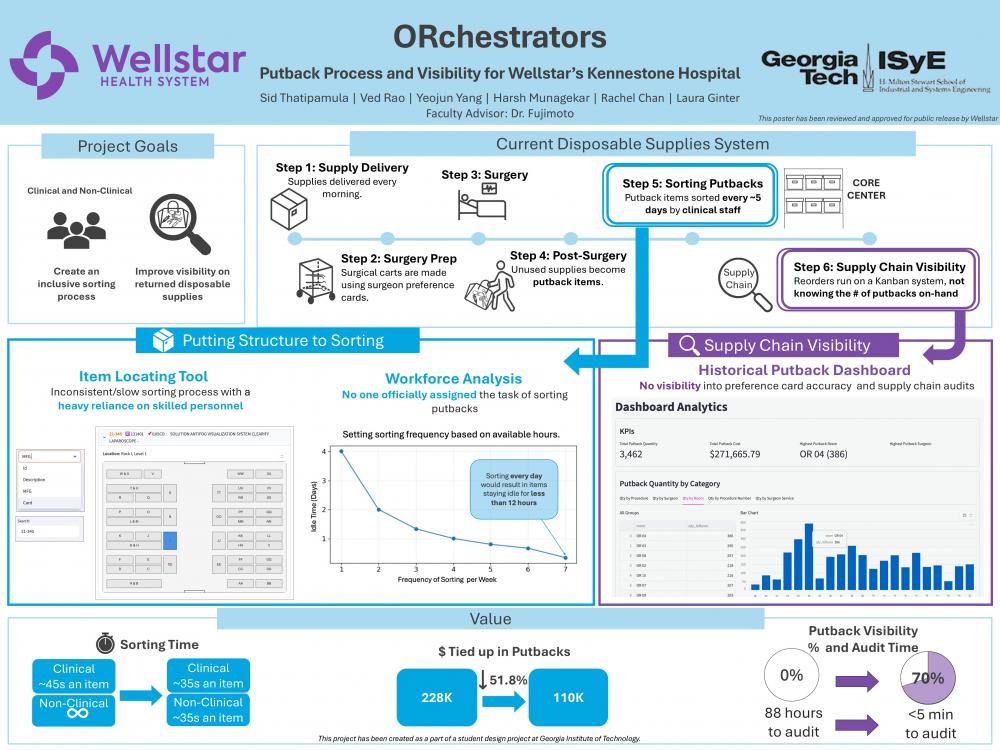

The client has identified inefficiencies in the supply putback process, where unused disposable items from previous surgeries remain unsorted for extended periods rather than being returned to inventory after the procedure ends. This delay contributes to unnecessary costs, material waste, and increased staff frustration, motivating efforts to improve efficiency within the perioperative supply chain.

Project Objective

The objective of this project is to improve the efficiency, visibility, and financial performance of the PeriOperative Services supply chain at Wellstar Kennestone Hospital by addressing major breakdowns in the surgical supply putback process. Currently, unused disposable items after surgery, putbacks, remain in unsorted piles across the inventory room for days due to lack of visibility, inconsistent sorting practices, and limited staff familiarity with supply locations to resort these items. These inefficiencies lead to unnecessary reordering, prolonged idle stock, and unorganized inventory storage for clinical staff. This project aims to develop workforce strategies and digital tools that reduce idle inventory time, standardize sorting processes, and expand the pool of staff who can meaningfully participate in putback sorting.

Design Strategy

The design strategy combines data integration and simulation modeling to address the core operational challenges of the putback process. First, the team integrated four siloed hospital datasets, operating room schedules, surgical supply guides, and supply utilization reports into a relational model to calculate putback KPIs through an inventory dashboard. Next, simulation-based workforce tools were developed to determine optimal staffing schedules needed to eliminate backlogs given real-world variability. Finally, a digital Locator Tool was designed using direct site observations of the Core Center’s physical layout and item organization, enabling any staff member to identify bin locations quickly. Taken together, the strategy ensures that each solution complements the others: visibility informs workforce planning, workforce planning is strengthened by faster sorting enabled through the Locator Tool, and all tools fit within existing OR workflows.

Deliverables

The project produced three deliverables. (1) Putback Visibility Dashboard: a fully automated data pipeline and Streamlit dashboard that quantifies putback volume, cost, and source drivers across surgeons, procedures, OR rooms, and item categories. (2) Workforce Analysis Tools (Tool 1 and Tool 2): Tool 1 simulates weekly staffing requirements and optimal sorting schedules to prevent backlogs, while Tool 2 identifies the highest-impact putback items to prioritize when resources are constrained. (3) Locator Tool: a digital item-location system that maps all 2,700+ SKUs in the Core Center and highlights precise bin locations, enabling non-clinical and temporary staff to easily search by item # or item description and locate their designated bins in the inventory room. Together, these deliverables provide a comprehensive framework to streamline inventory organization.

Value and Impact

This project delivers substantial operational, financial, and workflow improvements for Wellstar. The Putback Visibility Dashboard creates the first systemwide visibility into unused surgical supplies, reducing unnecessary reorders, and establishing a scalable audit process. Previously, an inventory audit took about 88 hours where staff would manually count each item and populate item details in an excel sheet. Now, staff can upload already existing data files and receive a comprehensive audit within 5 minutes. The Workforce Analysis provides clear guidance for how staffing and scheduling changes can reduce idle time by up to 60–80%, improving inventory availability and preventing premature replenishments. The Locator Tool expands the effective labor pool and cuts unfamiliar item sorting time by over 50%, making the sorting process more consistent and less dependent on institutional knowledge. Collectively, these solutions strengthen the reliability of the perioperative supply chain, improve labor efficiency, reduce waste, and enable a more sustainable and cost-effective operational environment for the Main OR.