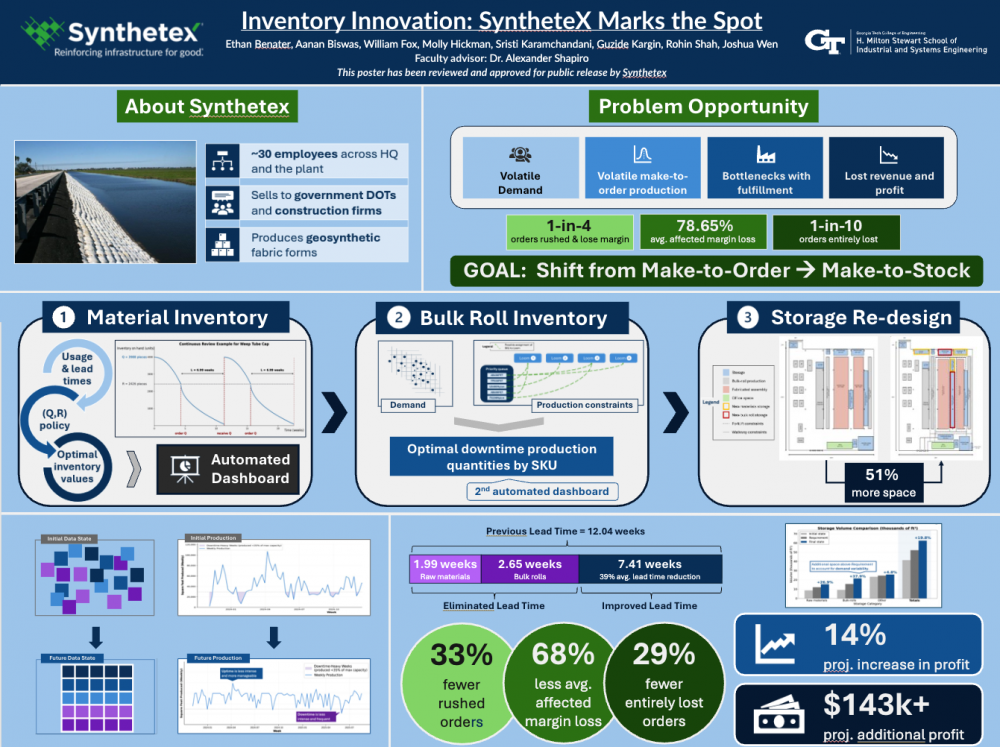

Client Context

Synthetex, LLC is a geosynthetics manufacturer headquartered in Peachtree Corners, GA, operating a 30,000 sq-ft production facility in Toccoa, GA.

The company produces HYDROTEX® fabric forms, which are woven geosynthetic fabrics that are filled with concrete and installed along waterways, roadways, ports, and infrastructure sites to provide long-term erosion control. The HYDROTEX® line includes 8 product families, 49 SKUs, and 100+ customization options.

Synthetex’s production system consists of three sequential stages: (1) raw material procurement and scheduling; (2) bulk roll production on weaving looms; and (3) fabricated panel production.

Synthetex’s previous business model was almost exclusively a make-to-order system with long lead times and severe production volatility. Very little on-hand inventory was held under this model.

Their demand is highly irregular and tied to cyclical construction, government, and infrastructure spending, causing the plant to oscillate sharply between periods of intense uptime (overtime, expedited production) and idle time (output capacity operating at or under 35%). As a result of this oscillation, Synthetex routinely experienced lead times from 12 weeks (on average) to periods as high as 6 months.

Project Objective

Synthetex’s leadership, following a strategic mandate from its parent company Geoquest, aims to grow profit substantially. However, the current make-to-order system causes the following: lost margins due to expediting during uptime (average 78.65% margin loss on expedited orders); lost orders when quoted lead times exceed customer tolerance (approximately 1 in 10 orders lost); long, unstable lead times averaging 12.04 weeks across stages; and underutilization of idle capacity that could otherwise build inventory.

The core design opportunity for our team was to help transition appropriate stages of production (raw material ordering and bulk roll production) to a hybrid make-to-stock system while keeping customization (the fabrication process) make-to-order, since customizations cannot be pre-produced.

The objective for this project was to help Synthetex shift to a hybrid make-to-stock system, enabling shortened lead time, stabilized production, reduced expediting costs, enhanced sales capture, and reduced labor turnover.

Design Strategy

The design strategy focused on three integrated design changes to transition Synthetex to a hybrid make-to-stock system.

Step 1: Raw Material Inventory Planning – (Q,R) Policy

- A continuous-review (Q, R) inventory model was built for 80+ raw materials. Key methodological elements included:

- Demand modeled using empirical distributions to capture skewness, zero-usage weeks, and heavy tails;

- Lead time modeled via a shrinkage estimator, blending supplier-level and material-level medians to address limited data;

- EOQ used to determine optimal order quantity Q;

- Service level balanced for both holding and stockout costs;

- Safety stock determined through rolling lead-time demand windows.

- Outputs were deployed in a fully automated Excel dashboard built using VBA and Power Query, with the ability to easily update the models with new demand data.

Step 2: Bulk Roll Inventory Planning – Capacity-Triggered Production Heuristic

- We created a periodic-review-based framework that informs inventory targets for each bulk roll SKU, based on historical demand and production data along with a rigorously optimized service level.

- A greedy assignment algorithm ranks machine–SKU combinations using a scoring rule that accounts for the inventory gap normalized by variability, any changeover penalties that might occur, and lastly reassignment penalties to avoid monopolizing looms.

- The output is delivered through a dynamic Excel tool that recommends which SKUs to produce and how much whenever idle looms become available.

Step 3: Storage Redesign – Systematic Layout Planning (SLP)

- Because the transition we recommended requires holding inventory, the team redesigned Synthetex’s production facility layout using Systematic Layout Planning principles. This included aligning storage with process flow, calculating cubic-foot requirements for each material category, and ensuring compliance with OSHA standards and client constraints.

- The redesign increased storage capacity by ~51% (from 41,211 ft³ to 62,438 ft³) and was delivered as a full AutoCAD layout.

Deliverables

Deliverable 1 was the Dynamic Raw Material Inventory Excel Dashboard that is based on our automated (Q, R) calculations and provides recommended EOQs for raw materials. The dashboard allows for easy data import from BoM and PO files and has dynamic visualizations for demand, lead time, and supplier performance. The purpose of this deliverable was to ensure that materials are on hand when orders arrive, eliminating material-driven delays.

Deliverable 2 was the Dynamic Bulk Roll Production Excel Dashboard that (1) recommends production assignments for available looms during idle periods; (2) leverages inventory gap, demand variability, and changeover logic; and (3) includes structured data sheets for future demand and production analytics. The dashboard intelligently recommends which bulk rolls and in what quantities to produce during idle time to reduce lead times and reliance on rushed production.

Deliverable 3 was a production facility layout redesign built in AutoCAD, which adhered to all OSHA rules and regulations, contained dedicated zones for raw materials, bulk rolls, and finished goods, and increased storage capacity by ~51%. This deliverable provides the physical infrastructure guidance needed to support the increase in on-site inventory levels from Deliverables 1 and 2.

Value and Impact

Lead time reduction:

The proposed design recommendations were estimated to reduce the average lead time from 12.04 weeks to 7.41 weeks, a 38.49% reduction.

Projected operational improvements include:

- Orders requiring expediting were reduced from 1-in-4 to 1-in-6

- Margin lost on expedited orders was reduced from 78.65% to 24.85%

- Orders lost due to lead time were reduced from 1-in-10 to 1-in-14

Financial impact:

Annual financial outcomes included the additions from the Margin Recovery (which reduced expediting) and the Net Sales Uplift from improved order capture while subtracting the necessary holding costs for new raw material and bulk roll inventory.

The net projected increase in profit was estimated to be about ~$144k annually, corresponding to a 14% uplift in Year 1 after subtracting the one-time storage transition cost of ~$8.6k.

Long-term strategic value:

Our recommendations will stabilize production and reduce labor turnover, create a clean, centralized data infrastructure for future decision-making, and enhance responsiveness to customer requirements and timelines through shorter lead times.