Client Context

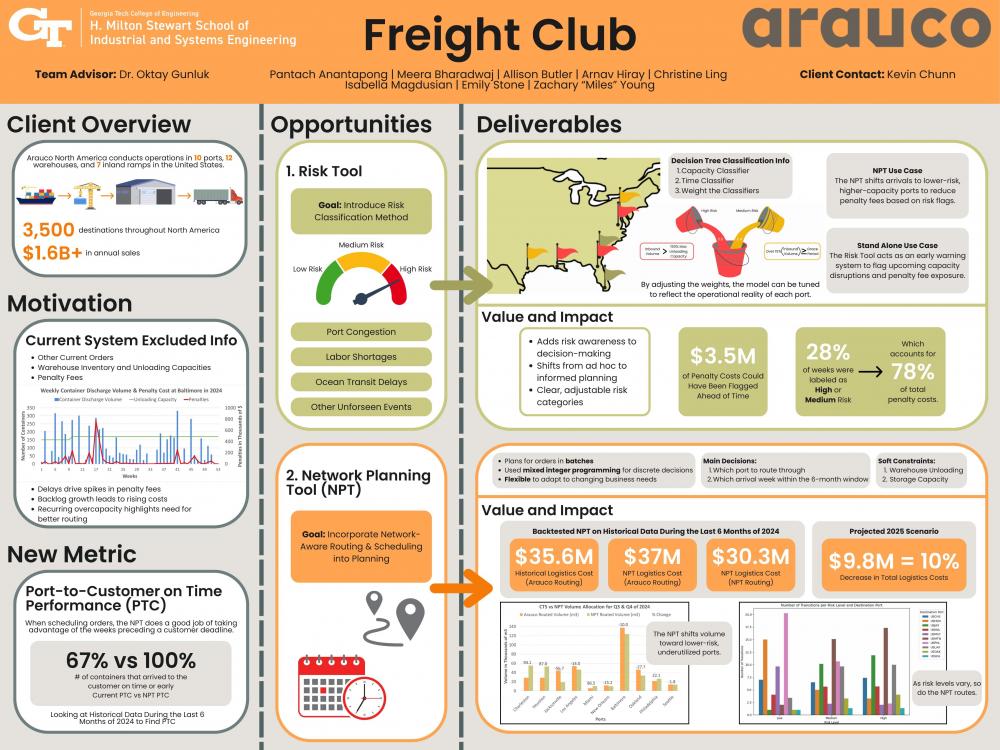

Arauco North America (NA) is a global manufacturer and supplier of sustainably-produced wood products such as plywood and moulding. Arauco NA is a subsidiary of Arauco, which is headquartered in Santiago, Chile, and operates over 20 production facilities across North and South America (SA). Arauco serves more than 3,500 destinations in North America alone, with annual sales exceeding $1.6 billion.

The client, Arauco NA’s Supply Chain Planning and Logistics teams, oversee order fulfillment and manage the third-party service providers that support container drayage, warehouse operations, and outbound transportation during the delivery process.

The project scope is focused on the shipment of orders from South America to the North American customers. As orders move throughout the network, Arauco makes decisions about how best to change order fulfillment plans in response to supply chain disruptions and congestion.

Project Objective

Arauco NA’s order fulfillment planning is exclusive to available warehouse storage and unloading capacity along with the whereabouts of all in-progress orders across the network. Consequently, Arauco NA incurs penalty fees, such as the $10.2 million faced in 2023 and 2024. Penalty fees are excessive unplanned logistic expenses that include container charges for demurrage, detention, chassis, and yard storage.

Arauco NA’s reactive routing and scheduling decisions contribute to increased congestion in their operations at ports and warehouses, which exacerbates port delays in the order fulfillment process.

One goal of the project was to increase awareness of how to anticipate the port risk of incurring penalty fees during order fulfillment in the short-term. The other goal was to help Arauco make low-risk, strategic routing and scheduling decisions to enable proactive planning in batches instead of on an order-by-order basis as the current system does.

Design Strategy

After studying Arauco’s current logistics network and meeting with their Logistics and Planning teams, we identified two opportunities: better risk visibility at the port level and more network-aware routing of orders. To address these, we developed two main tools: a Risk Classification Tool and a Network Planning Tool.

To support risk management, we created a weighted risk classifier that predicts weeks when a port might experience warehouse congestion or delays. We trained and validated the model on 2024 historical data, tuning it to maximize the rank correlation of our risk scores with penalty fees. Testing on unseen data showed that the classifier could successfully flag periods of elevated risk and potential service delays.

To improve shipment planning, we built a Mixed-Integer Linear Programming model that shifts Arauco’s process from one-order-at-a-time routing to weekly batch planning. We validated the tool by applying it to historical data from Q3 and Q4 of 2024, comparing the estimated total logistics costs to the actual historical costs. Our results confirmed that the model can route orders more efficiently while respecting constraints like warehouse capacities and customer request delivery deadlines.

Finally, because not all routes exist in historical data, we also developed a regression model to estimate logistics costs for new routes. We validated this model by running 100 rounds of randomized 80/20 train-test splits to check that it could accurately predict out-of-sample costs.

Deliverables

Our project focused on helping Arauco reduce costly delays and improve how it routes and schedules container shipments through its U.S. logistics network. We delivered two main tools to address separate but related challenges: flagging port-level risk and improving planning efficiency.

To support more proactive decision-making, we built a weighted Risk Classification Tool that flags ports likely to experience issues in a given week. These issues typically come from warehouse overload or slow container processing. The tool gives Arauco early warnings through a Graphical User Interface (GUI), allowing the logistics team to adjust before problems escalate. It can also plug into the Network Planning Tool by applying higher penalty fees to riskier ports, so the system is less likely to route through them unless necessary.

To improve how Arauco plans shipments, we developed a Network Planning Tool (NPT). This was implemented using a Mixed-Integer Programming model that shifts away from the current one-order-at-a-time process. Instead, the NPT uses batch planning at the weekly-port level, factoring in warehouse capacity limits, transit costs, and customer delivery deadlines. The model routes over 5,000 orders over a six-month horizon, incorporating a mix of client-provided demand and forecasted orders. It also helps with short-term decision-making when a port or warehouse becomes temporarily over capacity, giving Arauco the flexibility to reroute before bottlenecks turn into penalties.

Together, our tools and their associated Graphical User Interfaces help Arauco anticipate risk and act on it while planning more efficiently across their logistics network.

Value and Impact

The Risk Classification Tool effectively identifies periods of elevated risk. In analysis of 2024 testing data, only 28% of weeks were classified as high or medium risk; however, these weeks represented nearly 78% of total penalty fees. Had our risk scoring system been applied in 2024, it could have proactively identified around $3.5 million in penalty fees ahead of time.

By using our Network Planning Tool’s optimal routing and scheduling decisions, the client could have saved $5.3 million in total controllable logistics costs and seen a 94% decrease in penalty fees during the last six months of 2024.

Furthermore, if the client were to implement the NPT’s optimal routing and scheduling decisions for the full year 2025, they would see an estimated $9.8 million in savings which represents a 10% decrease in total logistics costs when compared to their current routing methodology.

These projected savings represent the culmination of our efforts to help Arauco make low risk, strategic routing and scheduling decisions and demonstrate the financial impact of such decisions even as logistics volume grows in 2025 by more than 25% and supply chain volatility persists.