Client Context

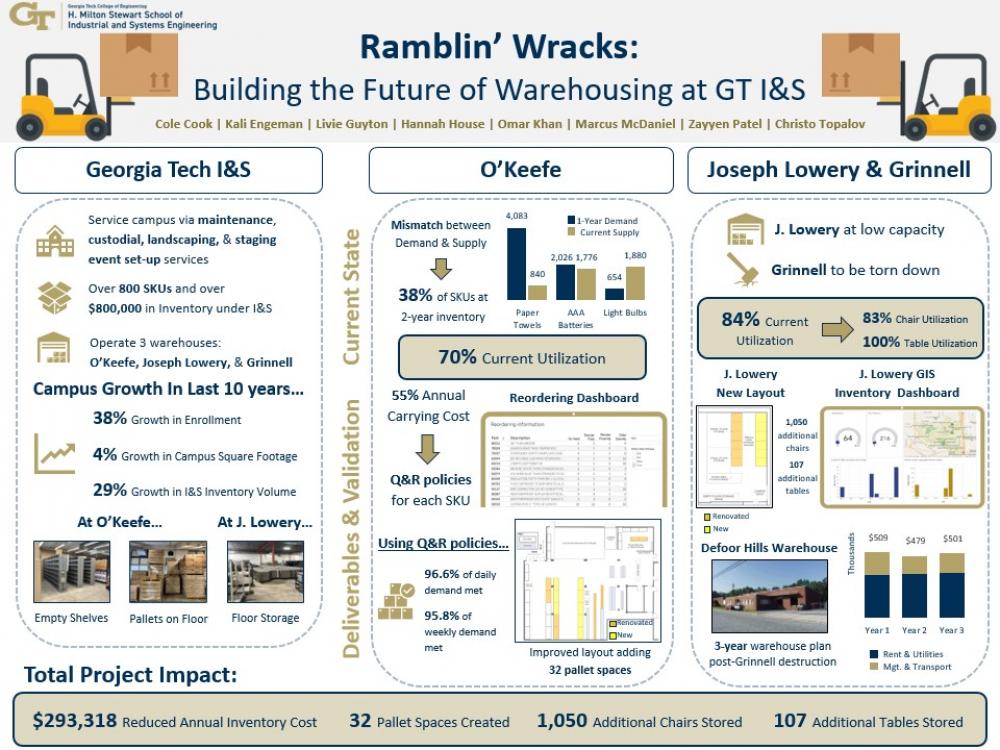

Georgia Tech (GT) Infrastructure and Sustainability (I&S) is a facilities maintenance group serving the GT campus. They operate out of three warehouses (O’Keefe, Joseph Lowery, and Grinnell) to provide maintenance and custodial supplies to areas of campus, event staging equipment and services, and swing space for the departments on-campus. The objective of the project is to reduce costs and build a plan for the future of I&S warehousing by efficiently using space, making data-driven inventory decisions, and consolidating operations.

Project Objective

GT’s current warehousing policies have created a perceived lack of space. After analysis, it became clear that the client is not losing space. In the O’Keefe warehouse, the quantity of new stock ordered is increasing per period, though the number of items being released is decreasing. This is partially due to the post-pandemic growth in the independence of their five distribution centers, dubbed Area Shops. We saw the following opportunities: evaluating ordering policies and creating an order management dashboard for the foreman, designing a new layout with more effective storage strategies, and consolidating the Area Shops into O’Keefe by storing new SKUs. The Joseph Lowery warehouse is near capacity but needs to buy more staging equipment to fulfill campus needs. We see the following opportunities for this space: creating a new layout to increase the storage capacity and streamlining the inventory tracking process with a dashboard. The Grinnell warehouse is not fully functioning and will soon be demolished, therefore the opportunity is conducting market research on the cost of renting a new warehouse. Each of these objectives allows I&S’s warehousing system to be more efficient.

Design Strategy

To understand how O’Keefe operates, the team measured O’Keefe, created a current layout of the facility, estimated the total capacity, and determined the average volume of an item within each category. Then a simulation was created in Simio to model the current state of the facility using this information to find the current utilization of the facility. The simulation was validated by comparing the confidence intervals to the true mean for each item category. Carrying cost was then calculated and a (Q, R) reordering model was developed, where Q is the reordering quantity, and R is the reordering point. This model was validated by backtesting the ordering policy against historic demand. Utilizing the new reordering policies and the current capacity of the system we were able to determine how much space could be freed up by reducing the amount of items ordered. Additionally, for the Area Shops we spoke with the managers to determine which SKU’s were currently ordered from third-party vendors and they would benefit from having stored in O’Keefe. In Joseph Lowery, the team measured the warehouse and created a current layout of the facility. After talking to the foreman about his goals for the warehouse we determined that a better layout could allow him to purchase new equipment that he has been planning to get for many years but lacked the space to store. Additionally, he mentioned a need for tracking his inventory that we believed could be easily implemented into his current system. With Grinnell being demolished I&S is in need of a separate swing space near campus that can hold the items currently stored in Grinnell; we considered many warehouses near campus comparing their costs and benefits.

Deliverables

We provided the client with the following deliverables: a dashboard for O’Keefe with new reordering policies, a layout for O’Keefe, a layout for Joseph Lowery, and a cost benefit analysis of renting new warehouse space. The dashboard for O’Keefe addresses the issue of overordering and frees up space in the warehouse by providing the client with easy access to the new reordering policies and automatically updates with current inventory data. The O’Keefe layout adds additional pallet spaces by utilizing an aisle system rather than a circular flow. The Joseph Lowery layout specifies certain locations for floor storage and adds more customized racks in order to increase the warehouse's capacity. The cost-benefit analysis compares three different warehouse situations in order to determine which would be the best for the client while minimizing potential costs. Each of these works to maximize the use of the space currently dedicated to I&S and helps them plan for the future to ensure they can efficiently serve the campus.

Value and Impact

Implementing the new reordering policy at O’Keefe would result in a one-time reduction in net working capital of $501,372, a yearly cost benefit of up to $275,640 and 10,400 ft3 of space made available (~19 pallet spaces). The new layout in O’Keefe increases the number of pallet spaces available by 38%. Both changes lead to increased storage space, which can be utilized by storing seven more SKUs in O’Keefe to assist the Area Shops’ ordering. The dashboard, which has been uploaded to the I&S servers, allows the employees to easily view the current inventory and when they should reorder items.

At Joseph Lowery, a new layout was created to accommodate an expected 2025 inventory purchase and results in an increased capacity of 25% more chairs and 37% more tables. A dashboard was connected to their existing system to allow the supervisor to see a snapshot of upcoming demand. Lastly, a cost analysis was provided for warehouse expansion to replace Grinnell. Once Grinnell is demolished, the recommendation is to move out of Joseph Lowery and combine with Grinnell into a new 22,300 ft2 facility located 4.5 miles from campus at an expected annual cost of $500,000.

The reduction in cash tied up in inventory at O’Keefe means that I&S may be more flexible and the additional cash can be used to pursue new growth opportunities. Adding SKUs to O’Keefes inventory to assist the Area Shops reduces lead times on those parts and allows the maintenance to be completed faster. The dashboard at Joseph Lowery allows the client to better manage their events and results in a more streamlined acceptance/rejection process. The scenario cost benefit analysis is beneficial for I&S to explore their warehouse space options and pursue system consolidation. The value of decreasing costs is not limited to the I&S organization but can also benefit the entire GT community by reallocating money saved from this project back to campus. Being on a fixed budget as an institute, Georgia Tech may use this redistribution to support research development, improve academic administration, or enhance other campus amenities.